Froth Pump

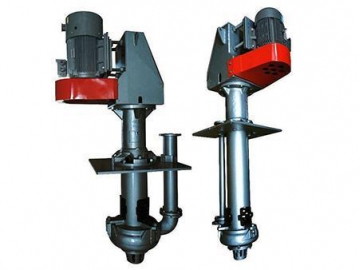

Froth Pump, EVF Series

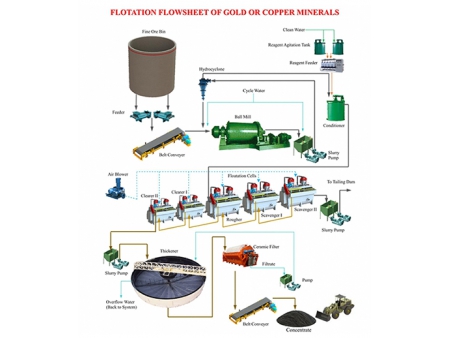

EVF series froth pump, as another branch of slurry pump, is characterized by its excellent transport of slurry mixed with foam. In particular, it is the most ideal product for operation in concentration plant, because the slurry often contains foam on flotation process.

Based on the introduction of domestic and foreign advanced technology, our company develops a new generation of product, called EVF series froth pump. This pump can effectively eliminate the foam in slurry at work. In the case of insufficient supplied materials, it can still work as usual. As an ideal product to transport foam type of slurry, our product is especially suitable for all types of flotation process.

EVF Series Performance Chart

| Model | Allowable Max Power P(Kw ) | Clear Water Performance | Impeller | |||

| Capacity m 3 /h | Head h(m) | Rotate Speed n(r/min) | Top Efficiency η% | Impeller Diameter D(mm) | ||

| EVF-2Q | 15 | 7.2-33 | 5-30 | 800-1800 | 45% | 229 |

| EVF-3Q | 20 | 10-104 | 10-28 | 700-1500 | 55% | 268 |

| EVF-4R | 40 | 15-130 | 6-28 | 500-1050 | 55% | 397 |

| EVF-6S | 75 | 55-330 | 6-25 | 350-680 | 55% | 560 |

Characteristics

1. This froth pump can adopt direct drive or indirect drive, convenient to replace the belt pulley for altering the rotate speed of pump so as to meet the changes of working conditions.

2. Besides, its work bin utilizes steel structure, stainless steel, steel liner rubber and so on. Its overflow box can conveniently return the excess supplied materials to the pool, and its tangential inlet makes the material quickly enter the pump and eliminate part of foam.

3. The head of pump adopts double pump shell structure. In accordance with different transmission medium, the overflowing components can utilize metal, rubber or other nonmetallic material.

Advantages

Our froth pump is specially designed for the working conditions with foam, which effectively solves the problem of transporting slurry mixed with foam on flotation process.

Scope of Applications

Nowadays we widely apply the froth pump to metallurgy, mining, coal, chemical and other industrial sectors for conveying corrosive or abrasive slurry mixed with foam.

Model Explanation

E: Excellence

V: Vertical Slurry Pump

F: Froth Pump

4: Discharge Size (Inch)

R: Frame Type

Structural Diagram

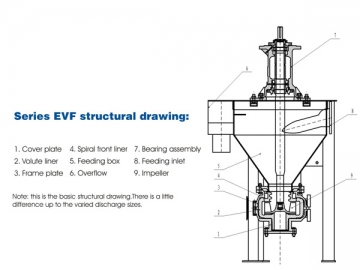

Series EVF structural drawing:

1. Cover plate 4.Spiral front liner 7.Bearing assembly

2. Volute liner 5.Feeding box 8.Feeding inlet

3. Frame plate 6.Overflow 9.Impeller

Note: this is the basic structural drawing.

There is a little difference up to the varied

discharge sizes.

Related Names

Double Suction Centrifugal Pump | Foam Slurry Transfer Pump | Mineral Processing Device