Gold & Silver Froth Flotation Plant

HZE's proficiency within the flotation process for gold, silver and other precious metals is unrivalled.

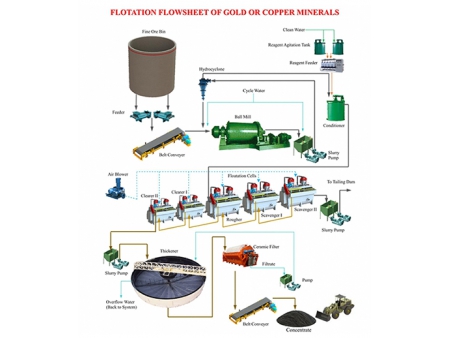

The flotation process is essential for extracting sulfide and free gold, and it requires the selection of suitable reagents for mixing with the slurry and recovery. Usually, there are three stages: roughing, scavenging, and cleaning.

The gold ore is first sent to the concentrator where it undergoes crushing, screening and grinding. Following this process, the ore slurry is directed to flotation.

Gravity concentration is usually applied in instances that the ore contains sizeable free gold particles. In these cases, additional equipment is typically added to the grinding circuit for recovering the gold.

If the ore has a higher oxide content, gold extraction through flotation can be challenging. This issue can potentially be solved by utilizing a combination of flotation and cyanide leaching processes.

It may be necessary to recover both the bulk concentrate and the by-product concentrate from the gold ore, as it could contain valuable minerals such as copper, lead, zinc or iron, in order to gain maximum benefit from it. This should be done taking into account the specific conditions of the ore.

After flotation, the concentrate is typically treated and filtered to remove moisture, then packaged and sent to smelter plants. The tailings generated from the process are either deposited into a tailings pond or dewatered and stored.