Li-Ion Battery Separator

The Li-ion battery separator is a microporous film with a main matrix of polyolefine film that has been manufactured using a one or two step stretching in hole crafts, and ion pass through functions. Li-ion batteries are known for the separate poles of positive and negative to avoid short circuiting. Following the development of separator technology, new types of li-ion battery separators have developed, including the PP/PE/PP compound separator, and ceramic coating separator. Each is characterized by the resistance to high temperatures, and the PVDF coating separator has one of the best performances on the market.

Product Features

We provide a complete range of articles and products in different thickness levels and different physical properties based on customer requirements, including a high security and excellent heat shrinking performance, anti-stretching and anti-threading performances, excellent compatibility with electrolytes, high liquid absorption and protection rate, and finally, an excellent electrochemical performance.

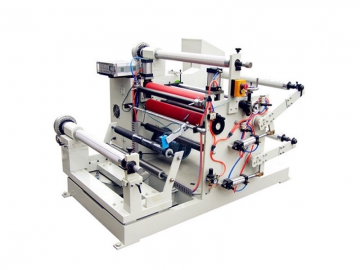

- Li-ion Battery Separator Production Procedure

- Li-ion Battery Separator half-product

- Li-ion Battery Separator End-product

| Model No. | Thickness | Porosity | Heat-Shrinkage | Gurley | Puncture Strength | |

| | USL | 22 | 41 | 2.5 | 450 | / |

| LSL | 18 | 37 | / | 250 | 300 | |

| CpK | 1.73 | 1.67 | 1.67 | 1.87 | 1.47 | |

| | USL | 27 | 41 | 2.5 | 550 | / |

| LSL | 23 | 37 | / | 350 | 375 | |

| CpK | 1.75 | 1.61 | 1.89 | 1.62 | 1.42 | |

| | USL | 34 | 43 | 2.5 | 650 | / |

| LSL | 30 | 39 | / | 350 | 480 | |

| CpK | 1.74 | 1.51 | 2.08 | 1.59 | 1.5 | |

| | USL | 42 | 43 | 2.5 | 750 | / |

| LSL | 38 | 39 | / | 450 | 600 | |

| CpK | 1.58 | 1.55 | 1.98 | 1.51 | 1.58 |

| Model | | | | | | | | | | ||

| Thickness | μm | GB/T6672-2001 | 8 | 10 | 12 | 14 | 16 | 20 | 25 | 32 | 40 |

| Gurley Value | s/100cc | JIS P8117 | 120 | 160 | 200 | 220 | 225 | 334 | 385 | 450 | 610 |

| Porosity | % | Q/CMZ1-2010 | 32.5 | 38.2 | 38 | 37.5 | 38.5 | 38.5 | 39 | 40.9 | 40.3 |

| Puncture Strength | g | Q/CMZ2-2010 | 180 | 200 | 228 | 300 | 302 | 375 | 482 | 534 | 627 |

| Stretching Strength | Kgf/cm2 | GB/T1040[1].3-2006 | 1350 | 1328 | 1327 | 1520 | 1322 | 1260 | 1297 | 1311 | 1384 |

| Heat Shrinkage | % | GB/T12027-2004 | 1.2 | 1.2 | 1.3 | 1.2 | 1.3 | 1.3 | 1.5 | 1.5 | 1.6 |

| MD (90 ℃ , 2h) | |||||||||||

| Heat Shrinkage | % | GB/T12027-2004 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| TD (90 ℃ , 2h) | |||||||||||