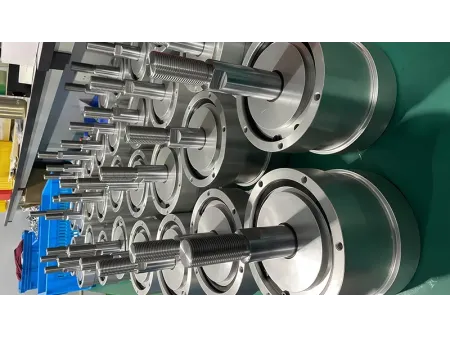

Pneumatic Cylinder, IS015552

DNC series pneumatic cylinder is a high-performance actuator designed for industrial automation. It can operate with compressed air or inert gases (e.g., nitrogen) and supports operating temperature from -20℃ to 80℃, pressure resistance up to 1.0MPa (1.5MPa for special models), and a quick reaction time up to 50ms to ensure quick start-stop performance. This cylinder comes with an IP67 protection level for dust and water resistance.

- ISO 15552-compliant, globally recognized, and easy to replace

- Reinforced aluminum-alloy structure ensures high durability and corrosion resistance.

- Low-friction sealing components deliver smooth motion without stick-slip

- High-load capacity supported by powerful thrust, meeting industrial demands

- Offers a wide bore size options (Ø32mm-Ø125mm) to meet diverse industrial demands

- Precision cushioning design effectively absorbs impact and extends service life

- TPU buffer pad offers superior wear resistance and stability for high-frequency cycles

- Inner wall covered with 3–5µm anti-wear coating, which provides minimal friction, low starting pressure for extended service life

- Custom size: Non-standard bore sizes of Ø12mm-Ø200mm; and stroke length up to 2,000mm

- Mounting options: Flange, foot, thin-type, or special-angle installation

- Material upgrade: In addition to the standard aluminum alloy body, stainless-steel cylinder barrel and piston rod options are available for corrosion-resistant or food-grade applications

- Functional enhancements: Built-in magnetic ring or external high-precision displacement sensor (±0.1mm); adjustable air cushion or hydraulic damper; integrated speed control valve and throttle silencer

- Protection level: Up to IP69K-rating, suitable for high-pressure washdown environments

- Operating conditions: Supports high-temperature (−40°C to 220°C) and vacuum applications

- Interface & compatibility: Multiple port thread standards and accessory pre-installation options available for complex assembly requirements

- Component Protection

Ensures precision and specification accuracy during pneumatic cylinder manufacturing.

- Post-Assembly Inspection

Verifies completeness and checks all cylinders’ parts for surface scratches or defects.

- Load Testing

Confirms pneumatic cylinder can withstand angular and lateral forces under load.

- Underwater Immersion Test

Ensures the cylinders remain completely airtight with no leakage.

- Woodworking Machinery

The pneumatic cylinder fixes cutting tools in place for wood and panel processing.

- Disassembly Fixtures

The pneumatic cylinder secures products for manual assembly and disassembly.

- Garment Processing Equipment

The pneumatic cylinder secures the clothing for the ironing process.

- Palletizing Machinery

The pneumatic cylinder controls the robotic arm rotation and pallet stacking movement.