Solder Preform

Request a Quote

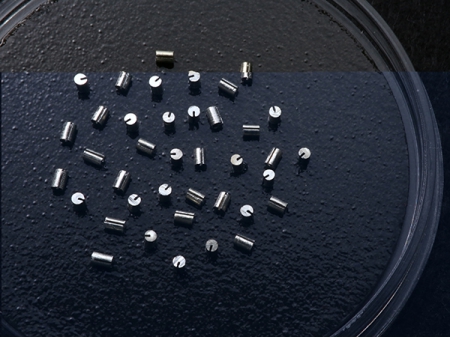

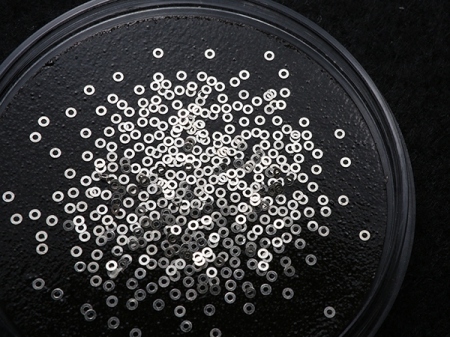

Solder Preforms come in standard shapes such as squares, rectangles, washers and discs. Customized shape can be available upon request.

Alloy OptionsAu80Sn20

Au88Ge12

Au10Sn90

Au80Cu20

Ag72Cu28

AgCu30Sn10

SAC305(Sn96.5Ag3.0Cu0.5)

SAC405(Sn95.5Ag4.0Cu0.5)

Sn98.5Ag1.0Cu0.5

Sn63Pb37

Sn90Sb10

Sn96.5Ag3.5

SAC405(Sn95.5Ag4.0Cu0.5)

Sn98.5Ag1.0Cu0.5

Sn63Pb37

Sn90Sb10

Sn96.5Ag3.5

In52Sn48

In97Ag3

In100

Pb92.5Sn5Ag2.5

Bi58Sn42

Bi57Sn42Ag1

In97Ag3

In100

Pb92.5Sn5Ag2.5

Bi58Sn42

Bi57Sn42Ag1

Application Examples

The solder preforms are used in a variety of applications such as:Die attach of semiconductor, LED and laser chips, thermal fuses, sealing, thermal interface, connectors and cables, vacuum and hermetic seals and gaskets, PCB assembly, mechanical attachment, package/lid sealing.

Solder preforms are used in conjunction with solder paste to precisely increase the amount of solder.

Solder preforms gaskets eliminate the need for secondary soldering processes.

SMT solder preforms with carrier tape packaging, simple operation and improved economic efficiency

- IGBT Module package

- Power switching transistor package

- Case package

- Thick film circuit package

- Management system: ISO 9001, IATF16949

- Uses high purity raw material (Tin - 5N, gold and silver - 4N )

- Has strict control on using times of raw materials

- Composition and melting point testing must be performed on each batch of products.

- Random inspection according to the standards of GB/T2828S-3

- Dimensional inspection

100% appearance inspection

Performance inspection: oxidation, ductility, soldering - Performs strict quality control on the sample, the first finished product and final product.