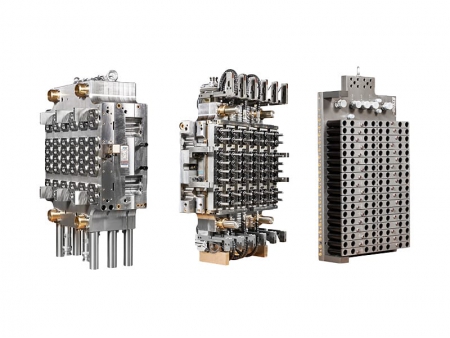

PET Preform Injection Molds

Request a Quote

PET injection molds are high-precision injection molds engineered to produce PET preforms, widely used in packaging for beverages, edible oils, cosmetics, and more.

Applications

- Available blow cavity: 32 cavities, 48 cavities, 56 cavities, 72 cavities, 96 cavities, 128 cavities, 144 cavities

- Neck diameter: Φ28mm (1716, 1810, 1881) ,26/22mm, 29/25mm, Φ38mm, etc.

- Suitable for: injection blow molding machine from different brands including HUSKY, NETSTAL, SIPA, KM, HUAYAN, etc.

- Applications of preforms: used as beverage bottle, carbonated bottle, water bottle, edible oil bottle, medicine bottle, etc.

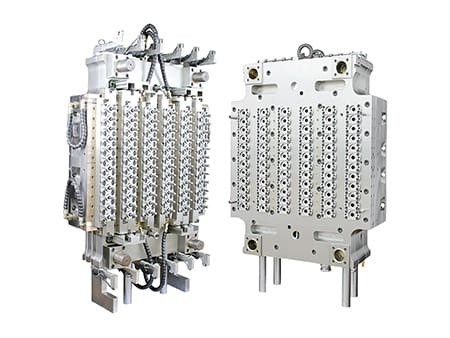

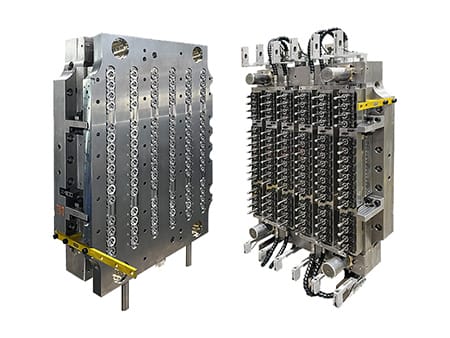

- Mold frame: made using S316 mold steel material and undergoes electroplating to achieve high corrosion resistance; hardness to within 30-35 HRC

- Life cycle: 10 million cycle times

Key Features

Absolutely. Provide your preform drawings and current equipment brand and model, and we’ll create a tailored plan. Once approved, we’ll put it into action.

For a preform mold quote, please include:

For just a cold half mold, share the injection machine brand and model, preform drawings, and cavity number. If the quote works for you, we’ll confirm further details as needed.

Yes, we conduct thorough testing before every shipment.

Definitely. Our experienced, expert design team is ready to provide lightweight design services tailored to your needs.