NPK Fertilizer Production Line, Steam Drum Granulation (50,000–600,000 t/y)

Request a Quote

Complete compound fertilizer production system using steam-assisted drum granulation process for uniform fertilizer granule formation

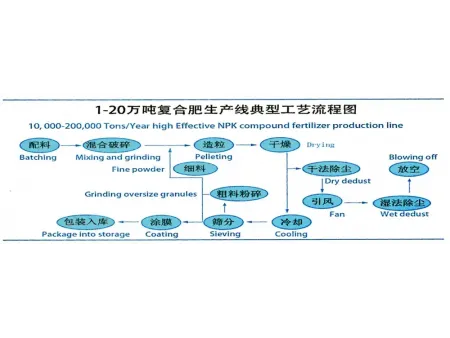

This NPK fertilizer production line is designed for manufacturing granular compound fertilizers and specialty fertilizers. It integrates multiple processing stages into a stable and well-coordinated system, ensuring consistent granule quality and reliable operation. The complete line covers raw material batching, granulation, drying, cooling, screening, coating, packaging, and exhaust gas treatment. Steam-assisted rotary drum granulation is used to ensure stable granule formation and consistent product quality.

- Production capacity: 5–600,000 t/y

- Standard: Complies with GB/T 15063-2020

- Granule size: 2.0–4.5 mm or 3.0–5.6 mm

Process Flow Diagram Features

- Patented technologies for stable and efficient operation

- The granulator, dryer, and cyclone dust collector adopt anti-stick internal designs, reducing material buildup, downtime, and maintenance frequency.

- Uniform material distribution inside the cooler ensures balanced airflow and consistent cooling of fertilizer granules.

- The screening system uses anti-blocking screen structures to improve screening efficiency and ensure consistent granule size.

- The coating unit is equipped with a patented atomizing spray nozzle, effectively preventing caking and improving the final product appearance.

- High-level automation control

- The production line is operated through a DCS distributed control system, enabling fully automated line operation.

- Key parameters such as raw material ratio, granulation temperature, drying moisture, and cooling airflow are automatically monitored and controlled, ensuring stable product quality while reducing manual intervention.

- Energy-efficient and environmentally compliant design

- A three-stage exhaust gas treatment system is configured to ensure emissions meet environmental regulations.

- Optimized drying and cooling processes help reduce overall energy consumption and lower operating costs.

Main Equipment

-

- Granulator

-

- Cooler

-

- Self-cleaning rotary drum screen

-

- Vertical crusher

-

- Vertical mixer

-

- Dryer

-

- Cage crusher

-

- Coating machine

-

- Cyclone dust collector

-

- Induced draft fan

-

- Bucket elevator

Finished Fertilizer Products

Explore Compound Fertilizer Production Line