NPK Fertilizer Production Line, Low-Tower Granulation (50,000–150,000 t/y)

Complete compound fertilizer production system using tower granulation process for uniform fertilizer granule formation

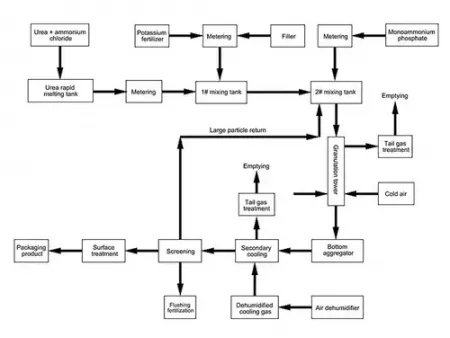

Low-tower melt slurry granulation process is adopted in this production line for manufacturing granular urea-based compound fertilizers. Urea melt or ammonium nitrate–phosphate solution is used as the liquid carrier and mixed with powdered phosphate fertilizers and potassium chloride or potassium sulfate to form a homogeneous slurry. The slurry is sprayed from granulation nozzles at the top of the tower and solidified through cooling, followed by screening, coating, and packaging to produce smooth, round granules with high mechanical strength.

- Production capacity: 50,000–150,000 t/y

- Standard: Complies with GB/T 15063-2020

- Granule size: 2.0–3.5 mm

Batching scale, Urea melting tank, Belt conveyor, Crusher, Bucket elevator, Granulation tower, Cooling unit, Air dehumidifier, Screening machine, Coating machine, Packaging machine, Exhaust gas treatment system

Features- The granulation tower height is reduced to approximately 60 meters. Total project investment is about half that of a high-tower granulation process with comparable capacity.

- Coal consumption is below 15 kg per ton of fertilizer when using thermal oil as the heat carrier, or steam consumption of approximately 160–180 kg per ton. Power consumption ranges from 15 to 22 kWh per ton.

- The system can operate reliably during hot and humid seasons, making it suitable for regions with high ambient humidity.

- Biuret content in the finished product is maintained at approximately 0.8–1.2%.

- Granule formation rate reaches ≥99%, with more than 90% of particles within the 2–3 mm size range. No wall adhesion occurs, enabling the production of high-, medium-, and low-concentration compound fertilizers.

- Finished fertilizer granules are evenly sized with consistent physical properties.

- Wet-based ammonium chloride can partially replace urea, reducing or eliminating the need for fillers and lowering compound fertilizer production costs.

- The process is well suited for producing compound fertilizers with reduced biuret (BIU) content.