NPK Fertilizer Production Line, Ammoniation Granulation (50,000–600,000 t/y)

Request a Quote

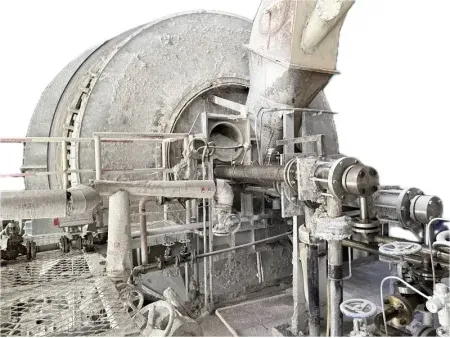

Complete compound fertilizer production system using ammoniation granulation process for uniform fertilizer granule formation

This compound fertilizer production line is designed for manufacturing granular compound fertilizers and specialty fertilizers. It integrates ammoniation and acidulation with granulation into a stable, well-coordinated process, ensuring consistent granule quality and reliable operation. The complete line includes raw material batching, ammoniation tank processing, pipe reactor reaction, granulation, drying, cooling, screening, coating, packaging, and exhaust gas treatment.

- Production capacity: 50,000–600,000 t/y

- Standard: Complies with GB/T 15063-2020

- Granule size: 2.0–4.5 mm or 3.0–5.6 mm

The ammoniation granulation process retains the advantages of steam drum granulation while offering the following additional benefits:

- The original steam granulation process route is maintained, ensuring stable operation and proven process reliability.

- Granulation temperature is increased to 70–80°C, resulting in lower material moisture and reduced drying load.

- Wet-basis ammonium chloride can partially or fully replace urea, reducing or eliminating the need for fillers and significantly lowering compound fertilizer production costs.

- Faster disintegration of compound fertilizer granules with fewer residues after dissolution.

- Reduced biuret (Biu) content during high-nitrogen and high-concentration fertilizer production.

- Higher granulation efficiency, with output increased by more than 30% compared with conventional drum granulation processes.

Ammonia-acid storage system