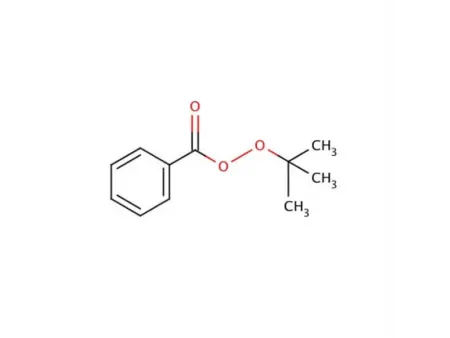

tert-Butyl peroxybenzoate (TBPB)

- Chemical Family Organic Peroxide

- Molecular Formula C₁₁H₁₄O₃

- Molecular Weight 194.2

- UN No. 3103

- Transport Hazard Class 5.2

- (organic peroxide, Type C, liquid, packing group II for dangerous goods)

Half-Life Period

- 0.1 hour 142℃

- 1 hour 122℃

- 10 hours 103℃

- Theoretical active oxygen content: 8.24%

- Purity: 98% min

- Available oxygen: 8.07% min

- Self-accelerating decomposition temperature (SADT): 65℃

- Hazardous temperature (Tem): 55℃

- Storage temperature (Ts min/Ts max): -15/25℃

- Activation energy: 151.59kJ/mol

- Decomposition temperature: 76-77℃

- Appearance: Slightly yellow clear liquid

- TBHP content: 1000mg/kg

- Inorganic/organic hydrolyzable chloride: 50mg/kg

- Boiling point: 124℃ (760mmHg)

- Density: 1.036-1.045 (25℃)

- Refractive index: 1.495-1.500 (25℃)

- Solubility: Insoluble in water, soluble in most organic solvents (can be diluted with the solvent specified by customer)

- Major decomposition products: tert-butyl alcohol, benzoic acid, methane, acetone, ethane, benzene

This peroxide is commonly used as a versatile initiator, curing agent, and vulcanizing agent across various industrial processes. Its ability to generate free radicals makes it ideal for promoting polymerization and cross-linking reactions, especially in the production of plastics, resins, and rubber products.

- TBPB is an effective medium-temperature initiator used in the production of low-density polyethylene (LDPE) through tubular and autoclave methods. Its performance improves when combined with other initiators such as tert-butyl peroxyneodecanoate (PV) and tert-butyl peroxy-2-ethylhexanoate (OT), creating a robust catalyst system that enhances polymerization efficiency.

- In suspension polymerization processes for styrene and styrene-based copolymers, TBPB is often used alongside benzoyl peroxide (BPO) to initiate the reaction, ensuring consistent and high-quality results.

- This chemical compound is frequently used in the polymerization of acrylates, offering a safer alternative to traditional azo initiators, reducing toxicity in final resins. It’s also used in vinyl acetate polymerizations.

- Widely used in the curing of unsaturated polyester resins, making it a suitable choice for processes such as SMC, BMC, and DMC molding. When combined with other initiators like BPO or TBPEH, it enhances the curing process, making it ideal for the production of fiberglass, coatings, and adhesives.

- TBPB is a highly effective vulcanizing agent for a range of rubbers, excluding isobutene-based varieties.

- By incorporating TBPB into fuels, it significantly enhances the cetane number, improving combustion efficiency and performance.

-

Packaging

This peroxide is supplied in 25 kg polyethylene drums, but custom packaging sizes are available based on customer needs.

-

Validity

When stored according to the manufacturer’s instructions, TBPB retains its quality for up to six months.

-

Safe Handling

Store the product in a cool, ventilated area where temperatures do not exceed 30°C.

Keep it away from heat sources, open flames, and incompatible materials such as acids, reducing agents, and flammable substances.

Ensure that storage areas have explosion-proof lighting and switches located outside the room.

Handle the product with care to avoid damaging the packaging and containers. Wear appropriate personal protective equipment (PPE) during handling.

Always refer to the Material Safety Data Sheet (MSDS) for detailed safety information.