Stone Crushing Plant

(Wheel Mounted Crusher)

Introduction

The wheel mounted stone crushing plant is serialized rock and construction waste crushing equipment developed by us. This mobile crushing plant has significantly expanded the concept of crushing operations. It is designed to eliminate barriers of crushing operations such as crushing site, environment, complicated base configuration and complicated logistics, to bring customers with efficient, cost-effective project operation.

Feed size: 1-750mm

Production capacity: 90-450t / h

Applications

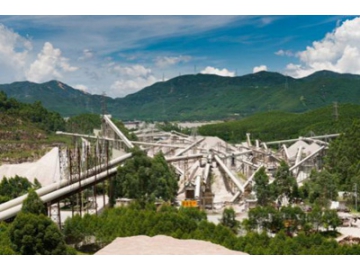

The stone crushing plant is widely used in mining ore crushing, construction waste recycling, construction aggregate production, highway, railway, bridge construction and other industries. (More applications, please click on the "free consultation")

Applicable materials: rocks and ores in a variety of hardness, such as granite, basalt, diabase, shale, sandstone, quartz stone, river gravel, limestone, iron ore, copper ore, manganese ore, coal gangue, non-ferrous metal ores, pebbles, etc.

Advantages

1. Flexible, diversified combination

With truck traction, compact structure, stableness and soundness, the wheel mounted crusher can fully satisfy the requirement on mobility either at operating site or on the road. The various models can be quickly matched with other models to meet the different needs of production operations.

2. Direct and effective operation, reducing material handling costs

Crushers in various models can work together in group to complete the on-site crushing. After crushing and screening, the materials will be ready for immediate use. The stone crushing plant also eliminates the step of transporting the materials away from the site being used to get crushed, which greatly reduces the cost on transportation.

3. Good adaptability, on-demand customization

The crusher plant can be equipped with independent generator sets. Even if the local power grid is not available, the machine can still work properly. At same time, we can offer specifically tailored mobile crushing station according to the customer’s site, material and grain-based requirements.

4. Reliable performance, easy maintenance

The stone crushing plant is using our high performance crusher, vibrating screen and vibrating feeder, so it has stable and reliable performance. Based on our many years of experience in manufacturing mobile crushing plant, the station is made with mature technology, which brings simple operation and easy maintenance.

How it works

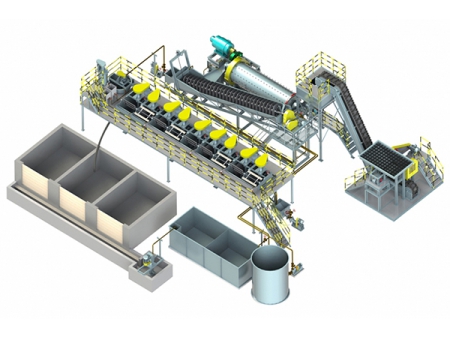

The main crushing equipment of the stone crushing plant is the crusher, which may be jaw crusher, impact crusher, cone crusher, etc. Materials are fed into the crusher by the vibrating feeder, and after primary crushing, the materials go into a closed system constituted by a circular vibrating screen to be crushed repeatedly. Finally, the finished materials that meet the size requirement are delivered by the belt conveyor. If the circular vibrating screen is not needed in the actual production, it can be removed, then only primary crushing is done and the other crushing equipment can finish the other steps. The stone crushing plant is convenient and flexible to use.

| Model | |||

| Transport length(mm ) | 11900 | 13100 | 14600 |

| Transport width(mm ) | 2550 | 2550 | 2950 |

| Transport height(mm ) | 3650 | 4450 | 4500 |

| Max length(mm ) | 12100 | 13300 | 14600 |

| Max width(mm ) | 2900 | 2950 | 3300 |

| Max height(mm ) | 4060 | 4810 | 5300 |

| Weight (T ) | 36 | 57 | 83 |

| Tire | Dualaxial C | Triaxial C | Triaxial C |

| Crusher model | PE600×900 | PE750×1060 | PE900×1200 |

| Max feed size (mm ) | 480 | 630 | 750 |

| Discharge opening (mm ) | 65~160 | 80~140 | 95~165 |

| Capacity (t/h ) | 90~180 | 110~320 | 220~450 |

| Feeder model | ZSW380*96 | ZSW490*110 | ZSW490*130 |

| Main belt conveyor model | B800×8.5M | B1000×9M | B1200×9.5M |

| Side belt conveyor model (option) | B450×3M | B500×3.5M | B650×4M |

| Generator power (option)(KW ) | 180 | 220 | 250 |

| Model | |||

| Transport length(mm ) | 11900 | 11900 | 13100 |

| Transport width(mm ) | 2550 | 2600 | 2900 |

| Transport height(mm ) | 3900 | 3900 | 4450 |

| Max length(mm ) | 12100 | 12100 | 13300 |

| Max width(mm ) | 2900 | 2950 | 2950 |

| Max height(mm ) | 4310 | 4310 | 4810 |

| Weight (T ) | 39 | 44 | 54 |

| Tire | Dualaxial C | Dualaxial C | Triaxial C |

| Crusher model | PF-1210 | PF-1214 | PF-1315 |

| Max feed size(mm ) | 300 | 300 | 350 |

| Capacity (t/h ) | 70~130 | 90~180 | 120~250 |

| Feeder model | ZSW380*96 | ZSW490*110 | ZSW490*110 |

| Main belt conveyor model | B800×8.5M | B1000×9M | B1000×9M |

| Side belt conveyor model (option) | B450×3M | B500×3.5M | B500×3.5M |

| Generator power (option) (KW) | 220 | 270 | 350 |

| Model | ||

| Transport length(mm ) | 14000 | 15200 |

| Transport width(mm ) | 3100 | 2830 |

| Transport height(mm ) | 4300 | 4350 |

| Max length(mm ) | 14000 | 16400 |

| Max width(mm ) | 3400 | 3400 |

| Max height(mm ) | 4700 | 4700 |

| Weight (T ) | 34.5 | 47.5 |

| Tire | Dualaxial C | Triaxial C |

| Crusher model | B75 | B160 |

| Discharge belt conveyor | B650×7M | B800×7.5M |

| Return conveyor 1 | B650×9.5M | B800×9.5M |

| Return conveyor 2 | B650×5M | B800×6M |

| Sieve belt | B800×6M | B800×7M |

| Vibrating screen model | 3YK1548 | 3YK1860 |

CHENGMING is a professional manufacturer of crushers and screens based in China. We keep on innovation and improvement to bring you the most satisfactory crushing solutions.