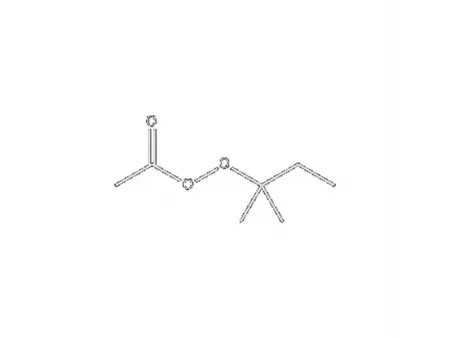

tert-Amyl peroxyacetate (TAPA)

- Chemical Family Organic Peroxide

- Molecular Formula C₇H₁₄O₃

- Molecular Weight 146.20

- UN No. 3107

- Transport Hazard Class 5.2

- Available in 70% and 50% solutions

Half-Life Period

- 0.1 hour 134℃

- 1 hour 114℃

- 10 hours 96℃

- Theoretical active oxygen content: 10.94%

- Purity: 70% min, 50% min

- Available oxygen: 8.96% min, 5.93% min

- Self-accelerating decomposition temperature (SADT): 60℃

- Storage temperature (Ts min/Ts max): --/30℃

- Activation energy: 152.16kJ/mol

- Decomposition temperature: 159℃

- Appearance: Colorless, clear liquid, diluted with various solvents such as benzene, odorless mineral oil (OMS), or isododecane, depending on the customer's requirements.

- Density: 0.923 (20℃)

- Refractive index: 0.1035 (20℃)

- Free acid: 0.5% max

- Solubility: Insoluble in water, soluble in most organic solvents

- Major decomposition products: tert-butyl alcohol, acetic acid, di-tert-butyl ether, methane, ethane

- This peroxide is an effective low-temperature initiator for high-pressure polyethylene (LDPE) polymerization, primarily used in tubular processes. It can be combined with other initiators like LQ-TBPV (tert-butyl peroxyvalerate), LQ-TBPEH (tert-butyl peroxy-2-ethylhexanoate), and LQ-TBPB (tert-butyl peroxybenzoate) to enhance polymerization efficiency.

- It acts as a high-temperature curing agent for unsaturated polyester resins, making it ideal for applications that require robust thermal properties.

- Additionally, it serves as an initiator for the polymerization of styrene and its copolymers, methyl methacrylate, and vinyl acetate.

-

Packaging

Standard packaging comes in 20 kg polyethylene barrels, with customizable sizes available upon request to meet specific customer needs.

-

Validity

When stored and transported according to the manufacturer's guidelines, the product maintains its quality for up to three months.

-

Safe Handling

Store in a cool, well-ventilated area, keeping the temperature below 30°C.

Keep away from open flames, heat sources, and materials like acids, reducing agents, and flammable substances.

Ensure that storage areas have explosion-proof lighting and proper ventilation.

Handle with care to avoid damaging the packaging or containers. Take necessary precautions to prevent impact or vibration during handling and transportation.

Customers are advised to carefully review the safety data sheet (MSDS) before handling or transporting.