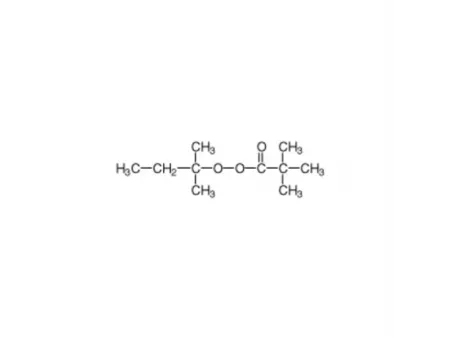

tert-Amyl peroxypivalate (TAPV)

- Chemical Family Organic Peroxide

- Synonym pivalate peroxypivalate

- Molecular Formula C₁₀H₂₀O₃

- Molecular Weight 188.3

- UN No. 3113

- Transport Hazard Class 5.2

- (organic peroxide, Type C, liquid, subject to temperature control in transport)

Half-Life Period

- 0.1 hour 91℃

- 1 hour 72℃

- 10 hours 55℃

- Theoretical active oxygen content: 8.5%

- Purity: 75.0 1% min

- Self-accelerating decomposition temperature (SADT): 25℃

- Hazardous temperature (Tem): 15℃

- Temperature control (Tc) : 10℃

- Storage temperature (Ts min/Ts max): --/-10 ℃

- Activation energy : 127.76kJ/mol

- Freezing point : < -23℃

- Appearance: Colorless, clear, oily liquid. It can be diluted with various solvents such as isododecane or odorless mineral oil (OMS), depending on the application or customer specifications.

- Viscosity: 2.1mPa.s (-10℃)

- Solubility: Insoluble in water, soluble in most organic solvents

- Chromaticity: 20APHA

- TBHP content: 1000mg/kg max

- Inorganic/organic hydrolyzable chloride: 150mg/kg max

- Major decomposition products: tert-amyl alcohol, methane, isobutane, acetone, methyl ethyl ketone, carbon dioxide

- TAPV is an effective initiator used in both tubular and autoclave polymerization processes for high-pressure ethylene production.

- Suitable for suspension polymerization of vinyl chloride (PVC) at temperatures between 50°C and 70°C, ensuring efficient reaction control.

- TAPV is used as an initiator for the suspension polymerization of acrylates and methacrylates. It is also effective in solution and non-aqueous dispersion polymerization processes, often used in the production of coatings.

- Widely used as an initiator in the polymerization of ethylene-vinyl acetate (EVA) copolymers.

- Works as a mid-temperature curing agent for unsaturated polyesters, typically used in hot pressing processes, with a curing range of 80°C to 100°C.

- Enhances the quality of oils when used as an additive, improving overall performance.

-

Packaging

Typically packaged in 20 kg polyethylene drums, which offer durability and protection during transport. If needed, customized packaging options can be arranged to accommodate specific client requests, ensuring flexibility for various industrial applications.

-

Validity

When stored and transported under the recommended conditions, the product remains stable for up to three months.

-

Safe Handling

Ensure the product is kept in a cool, well-aired storage area, ideally below -10°C. A constant temperature helps preserve product quality and reduces risks.

It’s essential to keep the product away from direct heat, flames, and reactive chemicals to prevent dangerous situations.

Avoid storing near acids, reducing agents, or any flammable materials. A separation of incompatible substances ensures safe handling and minimizes the chance of accidental reactions.

Gently handle containers to avoid spills, leaks, or damage to the packaging. Employees should wear protective gloves, masks, and other safety gear to avoid direct contact with the product.

For detailed guidance on safe usage, storage, and transport, always consult the Material Safety Data Sheet (MSDS) provided by the manufacturer.