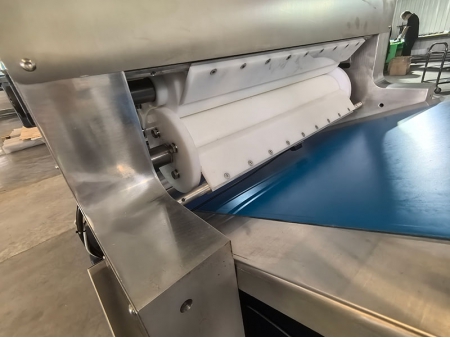

Two-Roll Dough Sheeter

Request a Quote

Horizontal Injection Line

Side Injector for Pastry Filling and Injection

- Model: SC-JP-2

- Size (L×W×H): 4080×1065×1350mm

- Power: 2 kW

- Weight: 510 kg

Two-roll dough sheeter is used in the front-end processing of croissants and other laminated pastries to evenly reduce the thickness of laminated dough sheets and prevent weight deviation in finished products. The sheeter adopts a two-roller structure, improving processing accuracy through bidirectional sheeting.

FeaturesAccurate and Even Dough Thickness

- Two-stage sheeting: During two sheeting stages—primary and final—the dough is rolled to a uniform thickness (typically 2–8 mm), with deviations controllable within ±0.5 mm, effectively resolving uneven thickness issues common in manual processing.

- Adjustable roller gap: Rollers' spacing can be flexibly adjusted via knobs or electric devices to meet different product thickness requirements, such as stuffed bun wrappers, dumpling wrappers, bread bases, and other bread products.

High-Efficiency Continuous Production

- Production line compatibility: Supports continuous dough feeding, such as with a dough conveyor belt, enabling rapid mass production. This dough sheeter is ideal for bakeries, central kitchens, and industrial food-processing facilities, with efficiency 5–10 times that of manual operation.

- Multi-product compatibility: Suitable for various dough types, including high-gluten bread dough (e.g., pizza bases and burger buns), medium-gluten bread dough, low-gluten biscuit dough, and more. This universal processing is achieved by adjusting the roller’s pressure and speed.

| Model | |

| Product Name | Two-roll Dough Sheeter |

| Size (L×W×H) | 4080×1065×1350mm |

| Power | 2 kW |

| Voltage | 380 V |

| Weight | 510 kg |

Looking for "Side Injector for Pastry Filling and Injection"?