Underground Diesel Wheel Loader

Overviews

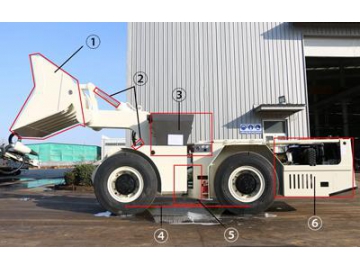

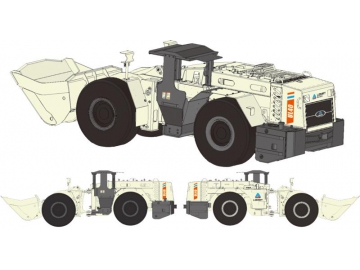

LGMRT underground diesel wheel loaders feature a compact body design in order to meet construction machinery and underground loading equipment characteristics. The loader can bear anywhere between 2.5 to 10 tons, and is primarily used to load, transport and dump underground rock from underground tunnels with harsh environments. The loader requires no electricity, and because it has no wires, it is mobile and more versatile than an electric loader. Diesel loaders are also suitable for loading mineral waste.

| Model | Payload capacity (kg) | Standard bucket capacity (m3) | Length (mm) | Width (mm) | Height (mm) | Unloaded weight (kg) | |

| UL20 | 2500 | 1.2 | 6090 | 1300 | 2000 | 7100 | |

| UL40 | 4000 | 2 | 7020 | 1790 | 2000 | 13200 | |

| UL50 | 4500 | 2.2 | 7135 | 1810 | 2000 | 13230 | |

| UL70 | 7000 | 3.5 | 8670 | 2200 | 2290 | 17152 | |

| UL100 | 10000 | 4.3 | 9742 | 2480 | 2390 | 27300 |

Higher reliability

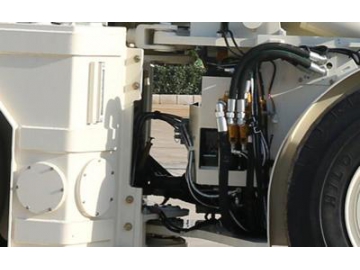

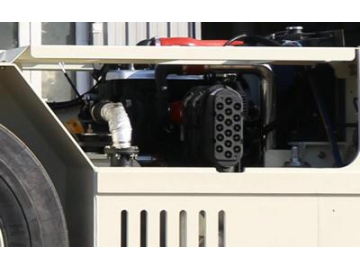

The underground loader uses hydraulic components from internationally renowned brands, including the US Permco oil pump, the US Eaton hydraulic tubing, the Germany Rexroth manifold valves and the American Dana drive axle.

Easier operation

All instrument and alarm functions are integrated into a single control panel, making it easy to observe the vehicle and working conditions at any time. The steering and working handle position is designed to be ergonomic and easy to operate. The underground loader features a wider working angle over other equipment, reducing blind areas and improving safety.

Easier maintenance

The manual lubrication system and pressure detection system on this loader are designed in a centralized manner. This makes it easier for staff to operate and maintain the loader. Simpler operation and maintenance saves both time and effort.