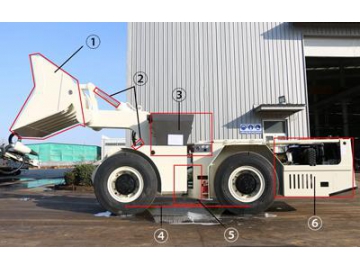

UD392 Underground Drilling Rig

LGMRT's UD392 underground drilling rig is a compact and flexible single-arm, electronically controlled hydraulic boring vehicle for underground mines and tunnels. Its excavation range reaches 34 square meters.

Equipped with an 18kW Sandvik HL510 hydraulic rock drill, the UD392 underground drilling rig achieves a higher perforation speed and service life. The sturdy boom's 360-degree rotation and self-leveling propulsion beam allow for fast and accurate drilling, and other multi-purpose drilling performances.

The UD392 underground rig uses heavy-duty four-wheel drive, articulated steering and a FOPS-certified safety roof. This ensures the rig safety and stability, even in small engineering tunnels. The rig features a broad field of vision, and in addition, it is easy to maintain and operate.

- Coverage area: 34 m2

- Rock drill model: HL510 (18kW)

- Feed beam: TF500-12

- Boom model: B26F

- Hole length: 3440 mm

- Turning width (T-section): 2750 mm

- Steering angle: ±35o

- Transport width: 1600 mm

- Transport height: 2070 / 2750 mm

- Transport length: 10065 (TF512)

- Total weight: 11600kg

- Model: HL510

- Power: 18 kW

- Percussion pressure (max.): 220 bar

- Percussion rate: 60 Hz

- Rotation speed (max.): 250 rpm (OMS80)

- Rotation torque: 400 Nm (OMS80)

- Hole diameter (drilling): 43-64 mm

- Hole diameter (reaming): 76-127 mm

- Shank adapter (Male thread): T38

- Recommended drill rod: T38-H35-R32, T38-H35-R35, T38-H35-Alpha330

- Weight: 130 kg

- Length: 1024 mm

- Profile height: 76 mm

- Type of control system: IBCQF, Hydraulic

- Drilling parameters adjustable

- Full power percussion

- Half power bolting

- Feed, rotation, and wash

- Automatic cycle: Anti-jamming, stop and return automatically

- Model: B26F

- Auto-parallel coverage: 29 m2

- Parallelism: Automatic hydraulic

- Boom extension: 1200 mm

- Feed extension: 1600 mm

- Boom net weight: 1850 kg

- Roll-over angle: 360 degrees

- Standard voltage: 380-690 V (±10%)

- Frequency: 50-60 Hz

- Total installed power: 70 kW

- Main switch gear: NSX160N/38

- IP classification: Specification TS2-132

- Starting method: Star delta starter 380-575 V

- Automatic cable reel: CR with tramming interlock

- Cable reel control:At the operator station

- Phase sequence protection: Automatic

- Front lights: (working + driving): 4 x48 W LED (24 V)

- Rear tramming lights: 2 x48 W LED (24 V)

- Operator station light: 1 *5 W LED (24 V) , yellow flash LED (24 V) , battery 2 * 12 V, 80 Ah

- Model: TF500-10, TF500-12, TF500-14, TFX6/12

- Feed force: 25kN, 25kN, 25kN, 25kN

- Total length: 4660mm, 5270mm, 5880mm, 3540/5370mm

- Rod length: 3090mm, 3700mm, 4305mm, 1830/3700mm

- Hole length: 2830mm, 3440m, 4050mm, 1610/3440mm

- Net weight (without hoses): 470kg, 500kg, 530kg, 620kg

- Flushing of holes: By water

- Water booster pump type: WBP1 (3kW)

- Water pump capacity: 33L/min, 15bar

- Inlet pressure: 4bar

- Water pump inlet pressure: 2-5.4 bar

- Flushing water pressure: 10-15 bar

- Shank lubrication device: SLU-1 (air/oil mist)

- Air compressor: CTN10, 1 m3/min (7 bar)

- Rock drill oil consumption: 200-300 g/h

- Rock drill air consumption: 250-350 L/min

- The canopy meets FOPS(ISO 3349) certification and protects the operator from falling rocks.

- Unit height in tramming: 2750 mm high position and 2535 mm low position.

- Sound pressure level: The sound pressure level on the operator station is up to 102dB.

- Operator’s seat: adjustable seat

- Powerpack: HPP 555 (55kW)

- Operating principle: Direct hydraulic control

- Hydraulic pump: 65cc+35cc+33 cc

- Oil filtration: 10μ

- Oil tank volume: 200 L

- Hydraulic oil filling pump: Electric pump

- Oil cooler: OW30 (30kW)

- Low oil level alarm and protection: Oil level indication and automatic shutdown

- Cleaning system with reel low pressure: Up to 15 bar

- Cleaning system with reel high pressure: Up to 180 bar

- Manual greasing system: Greasing unit with pump, reel and nozzle

- Spare rock drill: HL510

- Special tools for rock drill: Complete set

- Model: MERCURY (articulated steering)

- Steering angle: ±35 degree

- Rear axle oscillation angle: ±6 degree

- Ground clearance: 295 mm

- Engine: TCD3.6 L4 74 kW, Tier III, CN III

- Transmission: hydrostatic

- Wheel motors: 4 x radial piston

- Tires: 10-15

- Service braking: Hydrostatic

- Parking and emergency braking: SAHR Safety wet brakes

- Tramming speed: 8 km/h (horizontal), 4 km/h (14% = 1:7 = 8 degree slope)

- Grade ability: 15 degree

- Sideways tilt: 5 degree

- Fuel tank: 60 L

- Carrier stabilization: 2 x Telescopic (front), 2 x Vertical (rear)

- Brake release: Manual pump

- Centralized greasing point: Carrier

- Hand held fire extinguisher: 1 x 6 kg (ABC type)

- Tramming alarm: Standard

Documentation

1 x Operator’s manual

1 x Maintenance manual

1 x Parts manual

1 x CD of manuals (PDF format)