Conveyor Belt Cleaners / Scrapers

Conveyor belt cleaners, also known as scrapers, are key for the efficiency and longevity of conveyor systems. Their ability to remove adherent material from the conveyor belt not only enhances the conveying system’s performance but also reduces downtime due to equipment failure, lowering maintenance costs significantly. Choosing the right type of scraper can extend the life of conveyor belts, pulleys, and idlers substantially.

We offer conveyor belt cleaners available in various types, each suitable for different applications and material characteristics:

Polyurethane cleaners (GH/GP/GO) are known for their exceptional wear resistance, corrosion resistance, and gentle interaction with conveyor belts, making them ideal for a wide range of industrial settings including manufacturing, metallurgy, ports, mining, and coal transport. Carbide cleaners (H/P) are designed for durability and effectiveness in scraping off tough materials. Brush cleaners offer a gentle cleaning action, suitable for various materials. Conveyor belt cleaning system use water jets to clean, ideal for sticky or wet materials. Spring tension belt cleaner, hammer conveyor belt cleaner, and V-plough belt cleaners offer unique benefits for specific conditions, from heavy-duty cleaning to handling delicate materials.

GH Type Polyurethane Belt Scraper

The GH type polyurethane belt scraper is a primary cleaner located at the head pulley. It's suitable for conveyors transporting moist, corrosive materials at higher speeds. Installed at an angle of 15° to 30° to the conveyor belt's working surface at the conveyor head, it efficiently removes materials sticking to the conveyor belt.

GP Type Polyurethane Belt Scraper

The GP type polyurethane belt scraper is designed as a secondary belt cleaner, suitable for conveyor systems handling damp or corrosive materials at higher belt speeds. Located between the head pulley and the conveyor belt's smooth working surface, it removes material buildup, enhancing operational efficiency.

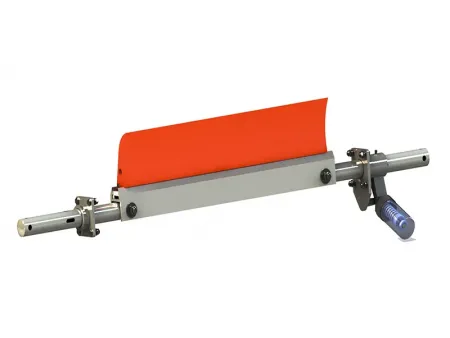

V-Plough Belt Cleaner

Our V-plough belt cleaners are designed for the return side of the conveyor belt, efficiently cleaning the non-carrying side without damaging the belt. Its scraper, made from high-quality, wear-resistant rubber imported from Germany, is engineered to have a prolonged service life and resistance to corrosion and breaking, ensuring high safety without harming the conveyor belt. The parallel mechanism frame of the cleaner maintains close contact with the conveyor belt, automatically adjusting its position in response to the wear of the cleaning blade and changes in the conveyor belt's position. This ensures effective and thorough cleaning. Additionally, its simple structure makes maintenance straightforward.

H Type Tungsten Belt Cleaner

The H type tungsten belt cleaner is a vital tool for maintaining the efficiency and smooth operation of your conveyor system. Made from high-strength tungsten, this device effectively removes material build-up on the conveyor belt, preventing jamming, damage, and other problems.

Compact and easy to install, the H type tungsten belt cleaner is ideal for a wide range of applications. The high-quality tungsten blades precisely remove adhered material from the belt, and the blade pressure can be easily adjusted to suit different material types and working conditions.

P Type Tungsten Belt Cleaner

The P type tungsten belt cleaner is a conveyor cleaning tool designed to effectively remove material buildup on conveyor belts. Installed on the head pulley, it strategically positions itself for precise cleaning after materials are discharged.

Unlike spring-based cleaners, the P type tungsten belt cleaner utilizes the elasticity of a rubber rod combined with high-strength tungsten blades. This dual action of the rubber rod and blades ensures thorough cleaning without damaging the conveyor belt itself.

Tungsten Belt Cleaner with Polyurethane Blade

Tungsten belt cleaners with polyurethane blades combine the durability of tungsten alloy with the flexibility of polyurethane, resulting in an innovative cleaning solution for conveyor belt systems. This type of scraper features the toughness of the alloy encapsulated within a polyurethane exterior, reducing the risk of damaging the conveyor belt. Its dual-material design enhances strength and wear resistance, outperforming single-material scrapers in terms of longevity and effectiveness. This belt cleaning tool ensures a more comprehensive removal of materials adhered to the conveyor belt, maintaining the system’s efficiency and prolonging the belt's operational life.

Spring Tension Belt Cleaner

The spring tension belt cleaners we manufacture at Yuxin Machinery are engineered to stay in close contact with the conveyor belt, due to its spring tensioner, ensuring efficient removal of coal dust and similar fine materials from the belt. This cleaner stands out for its ability to quickly and effectively absorb substances sticking to the drum.

Features

- The spring tension belt scraper is made from a polyurethane composite, molded in one piece for a smooth, straight edge. This ensures low friction, high wear resistance, and consistent cleaning performance, effectively removing fine particles and moist, sticky materials from the belt.

- This feature guarantees stable contact pressure between the scraper and the belt. The scraper's surface is made up of several narrow strips, equipped with void buffer holes for excellent adaptability to various belts.

- The low yet stable pressure not only maintains an outstanding cleaning effect but also significantly extends the lifespan of the scraper, typically three to five years, without causing damage to the belt.

Hammer Conveyor Belt Cleaner

The hammer scraper cleaner is positioned near the conveyor belt's head wheel, designed to tackle materials that stick close to this area. It's comparable to the P-type belt cleaner, featuring an innovative design that automatically adjusts the scraper's wear compensation through its own weight.

Hammer conveyor belt cleaners feature resistance to impact, wear, and corrosion, while remaining easy to adjust. It's particularly useful for primary cleaning in harsh conditions with high moisture or sticky materials, thanks to its ability to automatically compensate for blade wear and absorb vibrations. Its simplicity in structure also means it's easy to install and requires minimal maintenance, making it a practical choice for a variety of conveyor belt systems.

Motorized Belt Brush Cleaner

Positioned at the discharge drum at the head of the conveyor, our motorized belt brush cleaners are designed to clean materials stuck on the conveyor belt. It's effective against materials with high moisture and viscosity, such as powdery and granular substances that tend to cling to the belt.

This brush cleaner operates with a geared motor that spins the brush at a speed of 140 rotations per minute, allowing the brush bristles to sweep across the conveyor belt at a linear speed of 4 meters per second. This action efficiently removes adhered materials from the belt. Additionally, the gap between the brush and the conveyor belt can be adjusted to suit the specific conditions of the operation site, ensuring optimal cleaning performance without causing damage to the conveyor belt.

Conveyor Belt Cleaning System (Conveyor Belt Wash Box)

The conveyor belt cleaning system, also known as conveyor belt wash box, has a high-pressure water wash setup beneath the return path of the conveyor belt. This cleaning system is engineered to wash away mineral debris adhered to the conveyor belt, improving both safety and efficiency while reducing manual labor costs.

This cleaning method is effective for operations where conveyor belts accumulate a lot of debris, ensuring the belt remains clean for longer periods and reducing the frequency and need for manual cleaning. By using high-pressure water jets, the system ensures a thorough cleaning process without damaging the conveyor belt, making it an ideal solution for maintaining optimal conveyor belt performance in various industrial settings.