Hydraulic Oil Chiller

Request a Quote

-

Model: COA-1.6~COA-116

-

Cooling Capacity: 1.6-116.0kW

-

Temperature precision: ±0.5/±1.5°C

The hydraulic oil chiller is a critical device for maintaining stable operation of hydraulic systems. It uses forced refrigeration to precisely control the operating temperature of hydraulic oil, effectively preventing efficiency loss, seal aging, and component damage caused by excessive oil temperature. Widely used in injection molding machines, die-casting machines, and hydraulic power units, it significantly improves system stability, extends hydraulic oil service life, and ensures continuous production and machining precision.

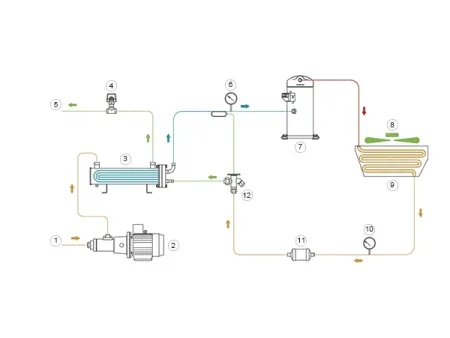

System Diagram

- Chilled oil outlet

- Pump

- Evaporator

- Flow switch

- Chilled oil inlet

- Pressure gauge

- Compressor

- Cooling fan

- Condenser

- Pressure gauge

- Dry filter

- Expansion valve

Specifications

| Model | | | | | | | | |||

| Cooling capacity | kW | 1.6 | 2.5 | 4 | 6 | 9 | 15 | 23 | ||

| 10³ kcal/h | 1.4 | 2.2 | 3.5 | 5.2 | 7.8 | 12.9 | 18.9 | |||

| Power supply | V/Ph/Hz | 380/3/50 | ||||||||

| Total power input | kW | 1.4 | 1.7 | 3.2 | 3.6 | 4 | 5.9 | 9.1 | ||

| Rated current | A | 5.1 | 6.4 | 12 | 13.4 | 9.2 | 12.3 | 21.2 | ||

| Temperature control | Constant temperature type /ambient temperature homogeneous | |||||||||

| Condenser type | High efficiency internal thread fin type | |||||||||

| Compressor | Type | Rotor type | Scroll type | |||||||

| Power | kW | 0.5 | 0.8 | 1.5 | 1.9 | 2.3 | 4.2 | 6.9 | ||

| Oil pump | Power | kW | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | |

| Flow rate | L/min | 20 | 20 | 40 | 40 | 40 | 60 | 90 | ||

| Safety protection | High/low pressure, overload, flow, over-temperature protection | |||||||||

| Pipe connection size | DN | 15 | 15 | 20 | 20 | 20 | 25 | 32 | ||

| Noise level | dB(A) | 60 | 60 | 62 | 62 | 65 | 65 | 66 | ||

| Weight | kg | 50 | 68 | 105 | 130 | 150 | 180 | 265 | ||

| Dimensions | Length | mm | 420 | 500 | 600 | 600 | 680 | 750 | 1350 | |

| Width | mm | 420 | 500 | 600 | 600 | 680 | 750 | 680 | ||

| Height | mm | 815 | 950 | 1160 | 1160 | 1360 | 1480 | 1360 | ||

| Model | | | | | | | | |||

| Cooling capacity | kW | 29 | 35 | 45 | 58 | 69 | 86 | 116 | ||

| 10³ kcal/h | 25 | 30.1 | 37.8 | 50.3 | 59.3 | 74.1 | 100 | |||

| Power supply | V/Ph/Hz | 380/3/50 | ||||||||

| Total power input | kW | 12.8 | 14.3 | 17 | 23 | 26 | 35 | 45 | ||

| Rated current | A | 27.5 | 27.4 | 31 | 45 | 50 | 66 | 83 | ||

| Temperature control | Constant temperature type /ambient temperature homogeneous | |||||||||

| Condenser type | High efficiency internal thread fin type | |||||||||

| Compressor | Type | Scroll type | ||||||||

| Power | kW | 8.7 | 10.1 | 12.5 | 17.4 | 20.2 | 25 | 34.8 | ||

| Oil pump | Power | kW | 3 | 3 | 3 | 4 | 4 | 7.5 | 7.5 | |

| Flow rate | L/min | 170 | 170 | 170 | 250 | 250 | 390 | 390 | ||

| Safety protection | High/low pressure, overload, flow, over-temperature protection | |||||||||

| Pipe connection size | DN | 40 | 40 | 40 | 50 | 50 | 65 | 65 | ||

| Noise level | dB(A) | 67 | 68 | 69 | 69 | 69 | 69 | 70 | ||

| Weight | kg | 310 | 330 | 420 | 620 | 670 | 780 | 1100 | ||

| Dimensions | Length | mm | 1510 | 1510 | 1785 | 2080 | 2080 | 2080 | 2200 | |

| Width | mm | 750 | 750 | 915 | 1050 | 1050 | 1050 | 1200 | ||

| Height | mm | 1480 | 1480 | 1630 | 1720 | 1720 | 1720 | 2135 | ||

Customized specifications are available upon request. Please