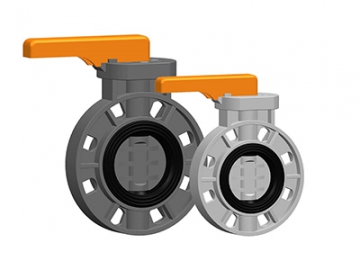

Metal Resilient Butterfly Valve

Metal resilient butterfly valve is a newly developed energy-saving valve product in KIST. It is used with water, steam, oil, air, and gas to adjust and control flow in food processing plant, medical plant, power station, sewage treatment factory, etc.

This valve is mainly consisted of body, disc, seal ring, and transmission part. Basing on the 2D or 3D eccentricity principle, and resilient sealing technique, the butterfly valve is of little operating torque and helps to save energy effectively. Besides, our metal seated butterfly valve is distinguished for good corrosion resistance, high temperature resistance, and abrasion resistance.

The manufacturing process of this butterfly valve is in line with the JB/T8527-1997 (metal sealed butterfly valve), the API 609-2004 (double flanged, lug type, wafer type), and the GB/T13927-1992 (common valve pressure test) standards.

Main Features

1. Metal resilient butterfly valve is of small volume and unique structure. It is portable and easy to be operated.

2. The sealing performance is in conformity with various standards.

3. It can be used to adjust flow.

4. With eccentricity principle, life of the valve is largely extended.

5. The butterfly control valve is applicable for medium of different temperature and corrosion degree. The pressure should be lower than 6.4MPa.

6. The valve body is designed with 2D eccentric structure and the sealing layer adopts resilient metal ring. The sealing layer of the disc and the valve body is contacted closely, allowing for reliable sealing result.

7. It is highly resistant to high-temperature, corrosion and abrasion. Generally, any construction requirements will be met with this kind of valve.

8. The 3-dimensional eccentric conical seat seal features little friction and self-cleaning function. It is operated manually, electrically, pneumatically, or by worm gear.

Materials (Customizable)

Body: WCB, WC6, Cr-Si-Mo steel, chromium titanium steel, duplex steel, chromium nickel titanium steel, low carbon steel, WC9

Disc: low carbon steel 6, duplex steel 6, stainless steel WCB, Cr-Si-Mo steel 6, 6 Cr-Ni steel, 6 chromium nickel titanium steel

Seat ring: Chromium nickel titanium steel 6, Cr-Ni steel 6, 6 duplex steel, WCB stainless steel, 6 Cr-Si-Mo steel, 6 low carbon steel

Shaft: low carbon steel, Chromium nickel titanium steel, Chromium molybdenum steel, stainless steel, Cr-Si-Mo steel, 6 Chromium nickel titanium steel

Sleeve: graphite stainless steel, duplex steel, bronze, Cr-Ni steel, stainless steel, carbon tool steel

Gasket: flexible graphite stainless steel, stainless steel graphite

Filler: flexible graphite