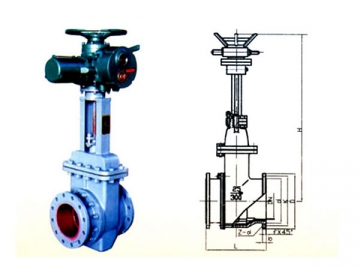

Resilient Seated Gate Valve

To avoid the problems like bad sealing, leakage, or rusting that commonly seen in gate valves, KIST has specially introduced the advanced manufacturing technology from Europe, and adopted integral rubber packing technique for fabricating resilient seated gate valve. This product is widely used as liquid regulator and shutoff valve in the pipelines of water plant, sewage treatment plant, food processing plant, drug manufacturing plant, metallurgical plant, and chemical plant, etc.

Main Features

1. Our resilient seat gate valve is known for reliable sealing performance and long service life due to the integral rubber covering technique, which allows for good covering performance and accurate dimension.

2. Made from ductile iron, the valve body features light weight and easy installation.

3. The flat seat design which is similar to that of the pipeline allows for no dirt accumulation and more reliable sealing performance.

4. The gate valve is highly anti-corrosive. Its inner cavity is specially coated with non-toxic epoxy resin to prevent rust and corrosion, making it applicable in waste water treatment and drinking water supply fields.

5. We have adopted 3 O-ring for sealing. It allows for little resistance, simple switch, and zero leakage.

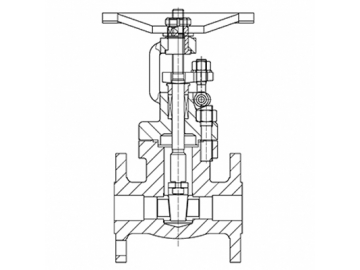

Materials for Option (customizable)

Valve body: ductile cast iron

Gate: ductile cast iron, EPDM rubber

Seal ring: nitrile butadiene rubber (NBR)

Bonnet: ductile cast iron

Stem: stainless steel

O-ring: nitrile butadiene rubber (NBR)

Trust pad: tin bronze

Shaft sleeve: tin bronze

Bolt: galvanized steel

Shaft cover: ductile cast iron

Dust cover: nitrile butadiene rubber (NBR)

Hand wheel: cast iron

Nut: galvanized steel