Central Granulator

Request a Quote

SG-43/50/70

Plastic granulator for recycling plastic wastes from injection moulding, blow moulding and extrusion machines

These central granulators are designed for the centralized recycling of plastics from various industrial processes such as injection molding, blow molding, and extrusion. These granulators are engineered with precision machining, advanced sound-proofing technologies, and energy-efficient motors, ensuring a high-performance recycling solution that minimizes energy consumption and operational noise, making them ideal for facilities prioritizing environmental and economic efficiency.

Features

- Precision machined cutting chamber and cutting tools: The cutting chamber components are precisely machined using CNC technology, ensuring reliability. The paddle blades are paired with presetting knife jig, which simplifies blade installation and adjustment. This setup allows for blade adjustments to be made outside the machine, significantly saving maintenance downtime.

- Automatic feeding system: Equipped with an automated material conveyance system that uses a blower to transport crushed material. This system not only improves efficiency but also cools the cutting chamber, effectively reducing temperature and preventing material fusion.

- High-efficiency cutting motor: Utilizes an IE3 high-efficiency motor, which reduces energy consumption while ensuring stable, safe, and reliable performance.

- Soundproofing design: The entire machine is enclosed in a sound-proof box, with sound-absorbing cotton placed in potential noise-generating areas to significantly reduce operational noise.

- Multiple safety protections: The control circuit complies with European CE standards, featuring motor overload protection, short circuit protection, phase loss protection, and phase sequence detection, ensuring safe operation.

- Cutting chamber cooling device: A cooling water device on the backplate of the cutting chamber effectively lowers temperatures, preventing the material from melting.

- Presetting knife jig : Features Presetting knife jig facilitates external adjustments of the moving blades, eliminating the need for difficult internal adjustments.

Applications

This series of central granulators are designed for recycling a variety of plastic materials in the plastic processing industry, including waste from injection molding, blow molding, and extrusion processes.

Specifications

| Model | ||

| Motor power (kW) | 30(37) | 37 (45) |

| Conveying blower power (kW) | 2.2 | 2.2 |

| Rotating speed (rpm) | 525 | 525 |

| Quantity of fixed blade | 2×1 | 2×2 |

| Quantity of rotating blade (optional) | 3×1(5×1) | 3×2(5×2) |

| Cutting chamber (mm) | 430×600 | 430×900 |

| Max. output capacity (kg/hr) | 800 | 1000 |

| Noise level dB(A) | 105~110 | 105~110 |

| Blade material | SKD11 | SKD11 |

| Diameter of screen mesh (mm) | ⌀12 mm | ⌀12 mm |

| Increased conveying blower power (kW) | 〇 (7.5) | 〇 (7.5) |

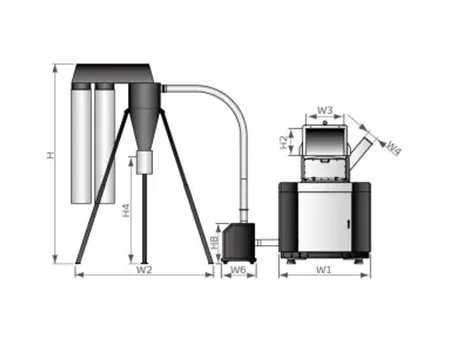

| H(mm) | 2710~3155 | 2710~3155 |

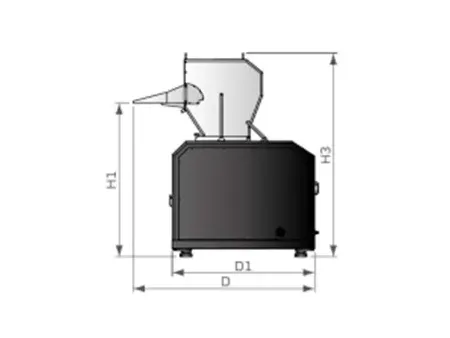

| H1(mm) | 1708 | 1708 |

| H2(mm) | 430 | 430 |

| H3 (mm) | 2260 | 2260 |

| H4(mm) | 1240~1690 | 1240~1690 |

| H5(mm) | 2277 | 2277 |

| H6(mm) | 750 | 750 |

| H7(mm) | 1268 | 1268 |

| H8 (mm) | 636(970) | 636(970) |

| W1(mm) | 1450 | 1750 |

| W2(mm) | 1900~2310 | 1900~2310 |

| W3(mm) | 600 | 900 |

| W4(mm) | 166x166 | 166x166 |

| W5(mm) | 720 | 720 |

| W6(mm) | 552(630) | 552(630) |

| D(mm) | 1978 | 1978 |

| D1(mm) | 1553 | 1553 |

| D2(mm) | 4300 | 4300 |

| D3 (mm) | 690 | 690 |

| Weight (kg) | 2350(2430) | 2730(2780) |

| Notes: | ||

| Notes: 1) "〇" stands for optional 2) SKD11 is JIS steel grade 3) The maximum output capacity depends on the diameter of screen mesh and composition of material 4) Noise level varies depending on different materials and motor types 5) Noise level test conditions:1m distance from the surrounding and 1.6m from the ground 6) Power:3Φ,400VAC,50HZ | ||