As an accessory product of our main laminating machines, the automatic sheet stacker machine can also be connected with the laminating machines from other manufacturers. This machine can automatically pile the laminated papers according to a specified number, which is an automatic machine integrating collection, stacking, intermittent turning and other functions. Realizing the front and back sides alternately placed stacking, it can effectively prevent the deformation of the cardboard after laminating, and reduce the labor intensity of the manual delivery. Compared with the same type of machine from other manufacturers, the parameter adjustment of this automatic sheet stacker machine is more intelligent. Input the paper size, the baffle and other parts of the machine can be automatically adjusted, and the working mode can be quickly switched.

According to the different paper sizes that can be processed by the existing laminating machine, we produce three different types of automatic sheet stacker machine for you to choose from. If there is any type of machine that meets your requirements, please contact us:

1450S automatic sheet stacker machine

| Max Sheet size | 1450X1250 |

| Min Sheet size | 500X500 |

| Overall | 5500X2600X2900 |

| Power | 6KW |

1650S Flip flop machine

| Max Sheet size | 1650X1450 |

| Min Sheet size | 500X500 |

| Overall | 5500X2800X2900 |

| Power | 6KW |

Features

- The paper baffle automatically adjusts the distance according to the paper size and paper quantity input by the customer to improve production efficiency.

- This machine has an automatic delivery function, which replaces manual delivery and saves labor.

- This machine is equipped with automatic fault detection and alarm devices, which is convenient for user management and operation.

Components

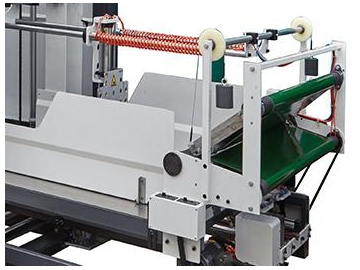

- Paper separating system: The fitted paper is dropped onto the down push system by the drive wheel and the timing belt pulley. After the set paper quantity is reached, the paper separation lever is lifted to separate the paper.

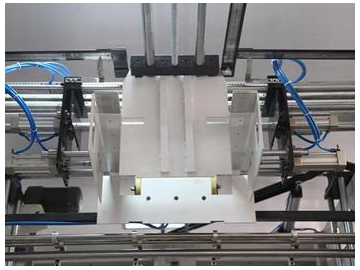

- Down push system: During the operation of the machine, the down push system automatically pushes a set number of sheets of paper into the turning system.

- Turning system: Stack the paper in turn, so that the fitted product is flat and not unglued, which is more convenient for post-print work.

- Up push system: Push the rising stack of paper into the delivery tray to be stacked

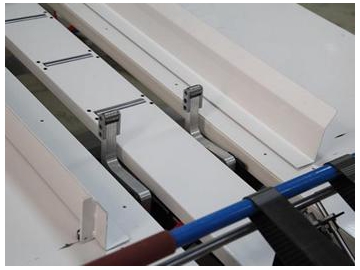

- Piling system: Take the paper on all sides of the paper to be aligned and ensure that the collected paper is neatly arranged.

- Collecting system: When the paper is stacked to a height of 1.7 meters, the delivery tray will be lowered automatically, and the whole stack paper will be pulled out by the hydraulic vehicle. And then the auxiliary delivery table automatically intervenes to complete the collecting of paper without stopping the machine.

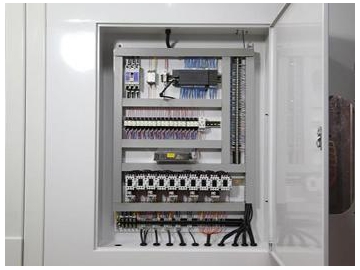

- Electronic unit: This machine is equipped with electrical components from well-known brands and has a function of one-button operation. This machine can automatically detect faults

- Pneumatic control system: The machine is pneumatically controlled and all pneumatic components are supplied by well-known brands such as Schneider, Siemens and NSK.

Product package