Pipe and Tube for Petroleum and Natural Gas Industries

- Steel pipes in the logistics park

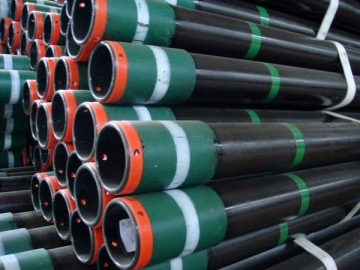

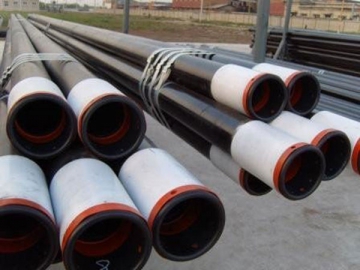

- Well processed steel pipes

- Well processed steel pipes

Advantages:

1. We can supply fast delivery: around 10 days for orders below 50 Metric Tons and around 30 days for orders up to 100 metric tons after L/C or Deposit

2. Quality Assured: Strictly acc. to ASTM & BS & EN & JIS, with System ISO certification.

3. Good Service: we supply professional technical guidance free of charge at any time.

4. Reasonable Price: to better support your business.

Package and Payment:

1. In bundle with strip or in bulk

2. First packed with a plastic bag then strip.

3. Surface treatment: Paint oil or brush varnish/paint.

4. Delivery: a. Container: For 20" container the max length is 5.8m; For 40" container the max length is 11.8m. b. Bulk carrier: No requirements for the length of the pipe.

5. Payment: T/T 30% in advance or LC st sight.

6. MOQ: 10T .

- Steel pipes

- Finished products

- Seamless steel pipe and tube for petroleum and natural gas industries

- Seamless steel pipe and tube for petroleum and natural gas industries

- Seamless steel pipe and tube for petroleum and natural gas industries

- Seamless steel pipe and tube for petroleum and natural gas industries

| Product name | petroleum and natural gas industry steel pipe | ||||||

| Process | Seamless, Cold drawn and Hot rolled | ||||||

| Specifications | Standard | API5L, API5CT, ASTM A106, ASTM A53, SY5037-2000, GB/T9711.1-1997, GB/T8162, GB/T8163, GB5130, GB3087, GB/T17396, JISG3445, ASTMA106, ASTMA335, ASTMA179, ASTMA519, EN10297, EN10210-1, EN10210-2, EN10025, EN10216, DIN1626, DIN1629, DIN17175, DIN17175, DIN2448 etc. | |||||

| Steel Grade | ASTM A106 GRB, A53 GRB. API 5L GRB,API 5 CT N80,K55,A335 P11.P91,DIN ST52,ST44,ST35.8,ST37,ST42,ST45,X42,X52,X60,X70 | ||||||

| Grade Level | Steel Grade | C≤ | Mn≤ | P≤ | S≤ | ||

| PSL1 | A25 | 0.21 | 0.6 | 0.03 | 0.03 | ||

| A | 0.22 | 0.9 | 0.03 | 0.03 | |||

| B | 0.28 | 1.2 | 0.03 | 0.03 | |||

| X42 | 0.28 | 1.3 | 0.03 | 0.03 | |||

| X46,X52,X56 | 0.28 | 1.4 | 0.03 | 0.03 | |||

| X60,X65,X70 | 0.28 | 1.4 | 0.03 | 0.03 | |||

| PSL2 | B | 0.24 | 1.2 | 0.025 | 0.015 | ||

| X42 | 0.24 | 1.3 | 0.025 | 0.015 | |||

| X46,X52,X56 | 0.24 | 1.4 | 0.025 | 0.015 | |||

| X60,X65,X70,X80 | 0.24 | 1.4 | 0.025 | 0.015 | |||

| Size | Outer Diameter | Wall Thickness | Length | ||||

| Inch | mm | Sch | mm | >=4m | |||

| 1/2"-16" | 25-356 | 40-XXS | 4-70 | unfixed, fixed | |||

| Application | These steel pipe products are widely used in petroleum and natural gas industries for fluid transportation without worrying about corrosion or physical damage. | ||||||

| Production Capacity | 35000 tons per month | ||||||

| Quality Assurance | Standard | ASTM,DIN,JIS,EN,GOST etc | |||||

| Test | Chemical Component Analysis | ||||||

| Mechanical Properties (Ultimate tensile strength, Yield strength, Elongation) | |||||||

| Technical Properties (Flattening Test, Flaring Test, Bending Test, Hardness Test, Blow Test, Impact Test etc.) | |||||||

| Exterior Size Inspection | |||||||

| Nondestructive Test (Ultrasonic flaw detector, Eddy current flaw detector) | |||||||

| Hydrostatic Test(The standard pressure is limited to 20,7 MPa (3000psi)) | |||||||

| Electro-magnetic inspection to SR1 is carried out on all line pipes | |||||||

| according to customers' request | |||||||

| Certificate | API, CE, ISO9001.2000.Mill Test Certificate etc | ||||||

| Inspection | Welcome you to send a third party inspecting company (BV, SGS etc.) to check the quality of our final products. | ||||||

| Main Market | Middle East,Asia, Europe. | ||||||

| Our Address | Economic Development Zone, Liaocheng City, Shandong Province, China | ||||||