Powder Spheroidization

The application of powder is continually advancing, requiring more from its performance. Alongside its low impurity content, fine particle size, and strict particle size distribution, it is important for the powder to have a particular morphology. The shape of these particles affects properties including surface area, fluidity, filling, chemical activity, and so on.

Spherical powder, especially when it is highly dispersed, has good fluidity due to its form. Its dispersion, larger surface area per unit volume and its physical and chemical properties make it a key role in more applications.

Carbon-based materials are currently the major materials of anode in lithium-ion batteries. Its performance has a direct impact on the cost, quality, and safety of the batteries. Alongside raw materials and process formulas, providing stable, efficient and energy-efficient technology for grinding, spheroidizing, shaping and classifying of carbon graphite is also important.

- GrindingBoth natural and artificial graphite need to be processed through several CSM710 units (name varies from different manufacturers) in order to achieve an end product of D50:20 μm powder. Depending on source material, the time of grinding cycles required may vary; for instance, large-flake natural graphite typically requires between 4 to 6 cycles, whereas the same process for artificial graphite will usually take between 1 to 3 cycles.

- SpheroidizationTypically, a CSM410 combined with a horizontal, high-precision turbine classifier is the desired setup for powder formation. The classifier is used to discharge the fine powder product during modification. Different raw materials require different formation cycles, with natural graphite generally requiring 8-12 cycles and artificial graphite calls for 2-4 cycles.

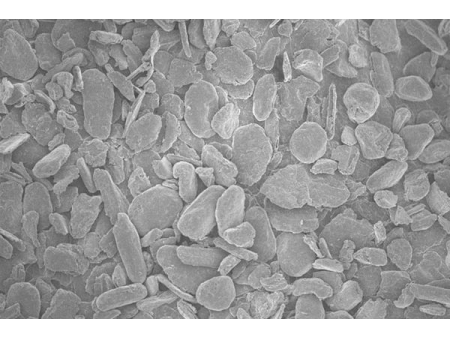

The raw materials are ground to an ultrafine powder by use of a single CSM710 special mill, reducing the average powder size to D50:21-23 μm. Spheroidized graphite particles with a particle size of 1920 μm (D50) are prepared by a process that a CSM510 spheroidizing machine is matched with a FW260 high-efficiency classifier unit, and the spheroidized graphite particles enter the CSM410 spheroidizing machine matched with the FW230 high-efficiency classifier unit through airflow conveying to become potato-shaped graphite particles with the particle size of 15-17 μm (D50);

Raw materials are evenly fed into the CSM710 special mill single tandem unit to produce ultra-fine powders with a particle size of D50: 23-25 μm, before fed into the next process of spheroidization. Then, CSM510 spheroidizing machines and FW260 high-efficiency classifiers were used together to prepare graphite powders with a particle size of D50: 19-21 μm. Finally, special surface modification and shaping equipment for graphite created qualified potato-shaped spheroidized graphite materials.

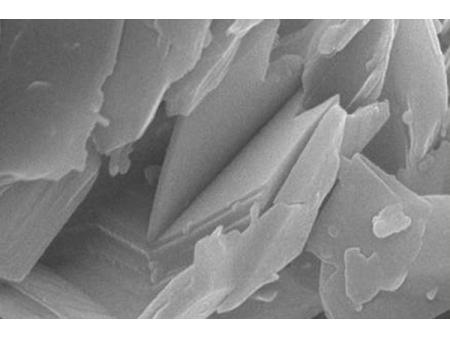

- Graphite carbon raw material

- After Model 710 grinding

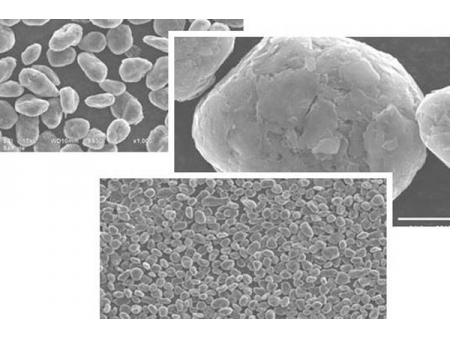

- After Model 510 spheroidization

- After Model 410 shaping

Spherical powder has gained wide acceptance due to its superior characteristics, making it a valuable choice for a variety of technology, product, and process applications.

- Application of Spherical Silica Powder Spherical silica powder is currently commonly used in packing large-scale integrated circuits and is increasingly being incorporated in advanced industries like aviation, aerospace, fine chemicals, and specialized ceramics. An essential element in epoxy resin systems, this powder can reduce material consumption by at least 30%, thus offering great potential in the market.

- Advantages of Spherical Silica Powder 1) Good surface fluidity, allowing for an increased amount of powders in the packaging of integrated circuits which leads to a smaller thermal expansion coefficient, improved dielectric capability, longer service life and enhanced performance of the produced electronic device. 2) The plastic packaging produced after spheroidization leads to reduced stress concentration and increased yield, shortening the production period and reducing the odds of product damage when being transported. 3) Uniform surface appearance, reducing wear on the die during production and post-processing, thereby lowering costs and increasing the service life of the die.

- Application of High Performance Spherical Titanium Powder Titanium powder is increasingly being used in the powder metallurgy industry due to its impressive mechanics, resistance to corrosion and thermal stability. High performance spherical titanium powder is one of the more popular varieties and has a number of desirable characteristics. These include high sphericity, consistent particle size distribution, malleability, plasticity, and tensile strength. This form of titanium powder is particularly useful for high-precision applications as it provides consistent compaction, higher accuracy and repeatable results.

- Application of Spherical Metal Powder Spherical metal powder is the essential ingredient when manufacturing products with metal 3D printing. As this technology continues to rapidly advance, the market for spherical metal powder can be expected to remain dynamic and highly profitable. In 2016, the industry as a whole was worth an estimated 250 million US Dollars.

- Application of Spherical Alumina The spherical micropowder has good press forming and sintering characteristics, making it an excellent choice for manufacturing high-quality ceramic products. Can be used as a grinding and polishing material to avoid scratches. In the petrochemical industry, spherical alumina powder can be employed to regulate the pore size and its distribution of catalyst-carrier particles by adjusting the size of the particles. Using spherical alumina as a catalyst can reduce abrasion and increase the durability of the catalyst, helping to reduce production costs.