Direct Buried Fiber Optic Cable

Description

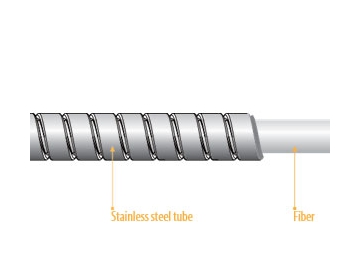

Because fiber optic cable is usually directly buried underground, it is wrapped in an outer armor to protect the cable against exterior mechanical damage and soil corrosion. We provide GYTA53 direct buried fiber optic cables for our customers, with the production process as follows. We first insert the 250um optic fiber into a loose tube made of high modulus material and then fill the loose tube with a waterproof compound. The loose tubes are then twisted around a central strength member coated with PE. A waterproof filler is added to the gap, and the cable core is then sheathed in a PE inner sheath. The APL is longitudinally wrapped and is extruded with a PVC inner sheath. The double-sided PSP is longitudinally wrapped and squeezed in a PVC outer sheath.

Standard

| Type (increase by two fibers ++) | Fiber count | Loose tubes | Fillers | Cable diameter (mm) | Cable weight (kg/km) | Allowable tensile strength (short/long term) (N) | Allowable crush resistance short/long term (N/100mm) | Bend radius dynamic/ static (mm) |

| GYTA53 2-6 | 2-6 | 1 | 5 | 16.8 | 255 | 1000/3000 | 1000/3000 | 10D/20D |

| GYTA53 8-12 | 8-12 | 2 | 4 | 16.8 | 255 | 1000/3000 | 1000/3000 | 10D/20D |

| GYTA53 14-18 | 14-18 | 3 | 3 | 16.8 | 255 | 1000/3000 | 1000/3000 | 10D/20D |

| GYTA53 20-24 | 20-24 | 4 | 2 | 16.8 | 255 | 1000/3000 | 1000/3000 | 10D/20D |

| GYTA53 26-30 | 26-30 | 5 | 1 | 16.8 | 97 | 1000/3000 | 1000/3000 | 10D/20D |

| GYTA53 32-36 | 32-36 | 6 | 0 | 16.8 | 255 | 1000/3000 | 1000/3000 | 10D/20D |

| GYTA53 38-48 | 38-48 | 7 | 1 | 16.8 | 255 | 1000/3000 | 1000/3000 | 10D/20D |

| GYTA53 50-60 | 50-60 | 8 | 0 | 19.2 | 320 | 1000/3000 | 1000/3000 | 10D/20D |

| GYTA53 62-72 | 62-72 | 9 | 1 | 19.2 | 320 | 1000/3000 | 1000/3000 | 10D/20D |

| GYTA53 74-84 | 74-84 | 7 | 1 | 19.2 | 153 | 1000/3000 | 1000/3000 | 10D/20D |

| GYTA53 86-96 | 86-96 | 8 | 0 | 19.2 | 320 | 1000/3000 | 1000/3000 | 10D/20D |

| GYTA53 98-108 | 98-108 | 9 | 1 | 21.2 | 380 | 1000/3000 | 1000/3000 | 10D/20D |

| GYTA53 110-120 | 110-120 | 10 | 0 | 21.2 | 415 | 1000/3000 | 1000/3000 | 10D/20D |

| GYTA53 122-132 | 122-132 | 11 | 1 | 22.3 | 415 | 1000/3000 | 1000/3000 | 10D/20D |

| GYTA53 134-144 | 134-144 | 12 | 0 | 22.3 | 415 | 1000/3000 | 1000/3000 | 10D/20D |

| Storage/Operating Temperature: -40℃ to +70℃ | ||||||||

| G652 | G655 | 50/125UM | 62.5/125UM | ||

| Attenuation (+20℃) | @850nm | ≤0.30db/km | ≤3.3db/km | ||

| @1300nm | ≤1.0db/km | ≤1.0db/km | |||

| @1310nm | ≤0.36db/km | ≤0.40db/km | |||

| @1550nm | ≤0.22db/km | ≤0.23db/km | |||

| Bandwidth (grade A) | @850 | ≥500MHz.km | ≥200MHz.km | ||

| @1300 | ≥1000MHz.km | ≥600MHz.km | |||

| Numerical aperture | 0.200±0.015NA | 0.275±0.015NA | |||

| Cutoff wavelength of optic fiber | ≤1260nm | ≤1450nm | |||

| Application: self-supporting aerial installation | |||||

- The direct buried fiber optic cable has an excellent mechanical property and temperature resistance.

- The loose tube material features an excellent hydrolysis resistance and higher strength.

- The special factice filled in the cable protects the fiber.

- The direct buried fiber optic cable has great stress tolerance and flexibility.

The following measures protect the fiber from water.

- The fiber optic cable uses a steel wire as the central strength member.

- The special waterproof compound is filled in the loose tube.

- 100% cable core filling.

- The APL moisture proof coating clads tightly around the cable core.

- The PSP improves the waterproof characteristics.

- High quality water blocking material prevents water penetration.