Haynes 188 Cobalt Based Alloy

Request a Quote

Cobalt-nickel-chromium-tungsten alloy

- 5772

Haynes 188 Cobalt Based Alloy

Physical and Mechanical Properties

Density

9.09g/cm³

Melting point

1300-1360°C

Tensile strength

860MPa

Yield strength

380MPa

Elongation

45%

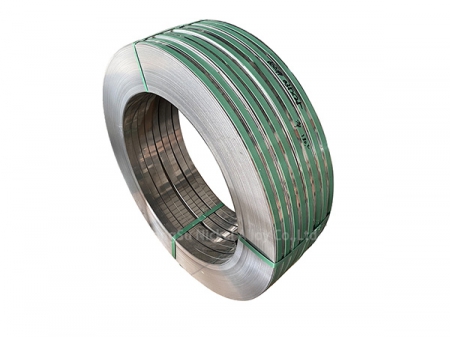

Product Form and Standard Specification

Bar

AMS 5772

Plate

AMS 5608

Wire

AMS 5801

Forging

AMS 5772

Haynes 188 (GH5188) is a Co-Ni-Cr based solid solution strengthened deformation superalloy, designed for high-temperature environments up to 1100℃. Its excellent high-temperature performance and weldability make it widely used in high-temperature components within the aerospace and energy industries. GH5188 not only boasts strong mechanical properties but also performs exceptionally well in high-temperature and corrosive environments, maintaining superior operational performance under harsh conditions.

Features- Excellent high-temperature strength: Maintains mechanical integrity and stability under extreme heat, making it ideal for turbine components and engine systems.

- Outstanding oxidation and corrosion resistance: Performs reliably in oxidizing atmospheres and chemically corrosive media, ensuring long-term durability.

- Superior wear resistance: High durability under friction and wear reduces maintenance frequency and extends equipment service life.

- Aerospace: Used in high-temperature engine components such as turbine blades and combustion chambers, ensuring reliable aircraft performance.

- Energy sector: Plays a key role in gas turbines and steam turbines, contributing to improved energy conversion efficiency.

- Industrial manufacturing: Applied in mold and tool manufacturing, where its wear resistance enhances the lifespan and productivity of precision equipment.

Chemical compositions

| Element | Min. % | Max. % |

| Ni | 20 | 24 |

| Cr | 20 | 24 |

| Fe | - | 3 |

| W | 13 | 16 |

| Cu | - | 0.07 |

| Co | Bal | |

| C | 0.05 | 0.15 |

| Mn | - | 1.25 |

| Si | 0.2 | 0.5 |

| S | - | 0.15 |

| P | - | 0.02 |

every aspect of materials testing, so our customers can achieve

consistent and accurate results, every time.

Providing High Nickel Alloys and High Performance Alloys