Rotary Disc Dryer

Request a Quote

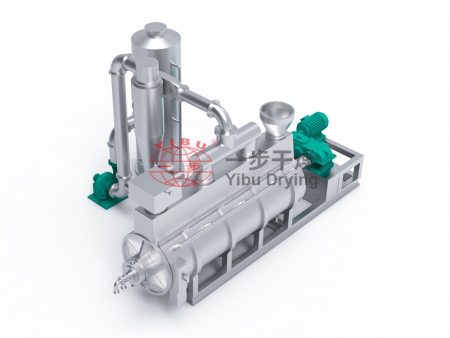

YQJ Series Rotary Disc Dryer

Designed for efficiency and reliability, the rotary disc dryer offers a compact yet powerful solution for processing pastes, powders, granules, and slurries. The disc-shaped blades provide a large heat transfer surface, optimizing thermal efficiency and minimizing heat loss. Its low-dust emissions and robust safety features make it a valuable option for industries that demand precise and safe material handling. With its ability to transfer heat on both sides of each disc, this dryer maximizes output while keeping the system compact and easy to operate.

Applications

- Organic chemicals

Ideal for processing PVC resin, PTFE resin, fumaric acid, anthraquinone, and other key organic compounds and intermediates - Inorganic chemicals

Handles materials like light calcium carbonate, active calcium carbonate, magnesium carbonate, sulfur, and ultrafine nano-sized compounds - Pharmaceuticals and food

Suitable for drying pharmaceutical ingredients such as ampicillin, cephalosporins, and vitamins, as well as food products like starch, chocolate powder, and corn germ - Feed and fertilizer

Efficiently processes feed-grade calcium phosphate, protein feed, grains, seeds, herbicides, and potassium-based fertilizers

Specifications

| Model | Power (kW) | Heat exchange area (m²) | Total volume (m³) | Dimensions (L×W×H) (mm) |

| | 15 | 30 | 1.97 | 5500×1300×810 |

| | 18.5 | 50 | 3.27 | 5600×1600×1000 |

| | 22 | 80 | 4.5 | 5200×1900×2700 |

| | 30 | 100 | 6 | 6400×1900×2700 |

| | 37 | 120 | 8 | 7200×1900×2700 |

| | 45 | 150 | 9 | 6200×2500×3000 |

| | 45 | 180 | 11.5 | 7500×2500×3000 |

| | 55 | 200 | 15 | 9000×2500×3000 |

| | 75 | 260 | 17.5 | 8600×2800×3300 |

| | 75 | 300 | 20 | 10100×2800×3300 |

| | 90 | 350 | 26 | 11000×3000×3650 |

| | 90 | 400 | 30 | 11500×3200×3750 |

| | 110 | 450 | 33 | 12000×3300×3950 |

| | 132 | 500 | 36 | 12500×3400×4100 |

Machine Structure Diagram

Features

- Heat is transferred through the blades, shaft, and inner wall, allowing for low energy consumption due to indirect heating, with minimal heat loss

- A high heat transfer coefficient shortens drying times, reducing equipment size and cutting down on building and operational costs

- Suitable for both heat-sensitive and high-temperature materials, the dryer can utilize various heating mediums like steam, thermal oil, or hot and cold water to meet different material needs.

- Air removes water vapor, keeping dust emissions low. For materials requiring solvent recovery or pollution control, the system can operate within a closed-loop or vacuum environmen

- With low rotation speeds and a durable design, maintenance and operating costs are minimized. The dryer can be easily managed by a single operator

Get in Touch

Need help finding the right product? Please fill the form and we will be in touch with you as soon as possible.