Non-Fried Flake Noodle Machines

It is well known that noodle comes in a great range of shapes and sizes. For this reason, as an expert of noodle machines, Dongfang Noodle offers non-fired noodle machines specially designed to make flake noodles that are similar to Maltagliati – diamond-shaped pieces of pasta. Whether you are a pasta factory willing to expend your facilities by adding noodle machines to make diamond-shaped noodles, or a new entrant looking for special noodle machines to perform all stages of noodle making process, we will be your reliable partner to provide you with individual commercial noodle machine solution.

As an experienced noodle production line manufacturer, we offer two types of flake noodle production lines which are used to manufacture non-fried flake noodles cooked in boiling water before eating, and instant flake noodles soaked 1 minute in boiling water before eating. Noodle flakes with various shapes can be manufactured by the noodle production equipment, such as rhombus, rectangular, and square. The flake noodle dryer can be equipped with a Teflon mesh conveyor belt or stainless steel conveyor belt upon request.

-

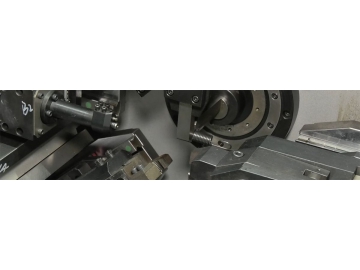

Continuous Dough-Sheet Rollerd

Dough sheet rolling machine adopts high-low rollers and four shafts feeding technology to ensure the smooth feeding. The external driving system makes the maintain easily, running stable and simple operation.

-

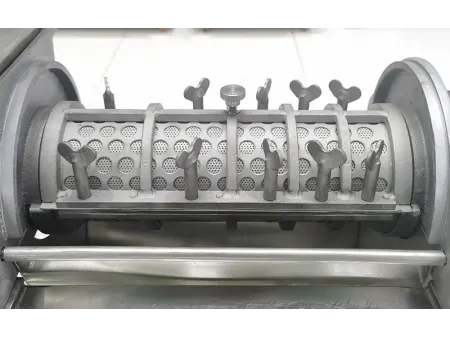

Swing Device

The pressed dough sheet is cut into noodle flakes by special knife, which fall on the conveyor belt, and slide to the swing device by sliding plate. The noodle flakes are scattered evenly on the dryer mesh through the left-right swing, and then enter into drying system. With this design, it greatly shortens the length of the noodle flake production line.

-

Multi Layer Steamer

The multi-layer steamer adopts water-sealing structure, with strong sealing ability and no steam leakage. The lifting type doors make the cleaing easily. The inner of steamer comes with reasonable spraying pipes, so that gelatinization is more effective.

-

Noodle Drying Machine

The five or seven layer dryer has two zones: upper area mainly for moisture removal, lower area for cooling and drying. It's designed with heat exchanger and air fans, which makes the heat energy recycled. Seven layers mesh makes the noodle flakes fully turn over, to prevent overlap and adhesion. With so ingenious design, the uniform noodle flakes can be dryed evenly and no crisp pieces are generated.

-

Noodle Cooling Machine

The dried noodle flakes are conveyed to the packing machine after air cooling.