Qatar--Concrete Cooling 30 Tons Flake Ice System

The Qatar project is a comprehensive flake ice project for concrete cooling, which integrates ice making, ice storage, conveying and metering functions. Due to the use of pre-contained equipment, most of the difficult installation work has already been done at the factory. With the efficient cooperation of the customer, the on-site installation took only 7 days to complete.

- Order time: June 2013

- Production cycle: 60 working days

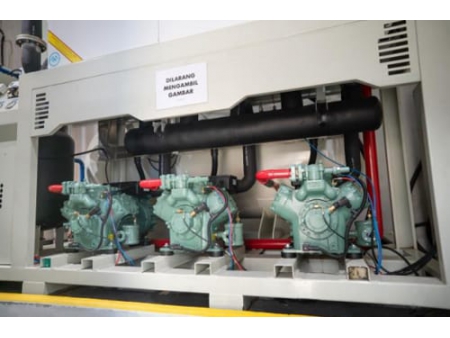

- Buy equipment: 3 sets of 10-ton water-cooled flake ice machines and 3 sets of 20GP containerized screw ice delivery systems.

- Installation Location: Qatar

The installation was completed on November 15, 2013. During the past installation, the customer had already set up the steel frame structure and the container-type ice storage warehouse had also been installed. When our people go to the local area, we directly use the crane to install the flake ice machine, install the motor of the screw in the ice storage warehouse, and install the cooling tower. The installation and commissioning time is less than 7 days before and after.

The purpose is to cool down ready-mixed concrete (ready-mixed concrete refers to cement, aggregates, water, and admixtures, mineral admixtures and other components added as needed in a certain proportion, and sold after being measured and mixed in a mixing station. And use the transport vehicle to transport the concrete mixture to the place of use within the specified time). The flake ice is fed to the automatic weighing device through the ice conveying screw, and the frozen water is added together with the flake ice, and the two are sent to the mixer together.