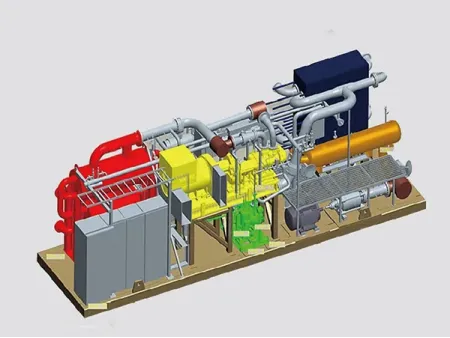

ORC Power Expander

ORC (Organic Rankine Cycle for power Generation) is a key technology in the field of low temperature waste heat utilization. It USES organic fluid as working medium to transform waste heat discharged from the upper energy system into high-grade energy, so as to improve the overall utilization of energy.

Organic working medium of the liquid by the circulation into heat exchangers, absorbing heat waste heat generated after a certain pressure and temperature of organic working medium steam, steam drive screw expander, doing work output of kinetic energy turns a generator to achieve power, steam exhaust discharge of low-pressure organic expander working medium entering the condenser heat release, condenses into liquid organic substance, again through the circulating pump back into the heat exchanger, so cycle to achieve the transformation of heat energy and kinetic energy.

The ORC (Organic Rankine Cycle) oil injection power expander is primarily utilized in scenarios where there are low-grade heat sources ranging from 80°C to 250°C. Typical applications include capturing and converting waste heat, waste steam, and flue gases generated during processes in oil refining, steel making, thermal power generation, and chemical synthesis. Additionally, it is applicable in emerging energy sectors such as geothermal power generation, solar power, and biomass energy production.

Technical Data| Model | Nominal Power Generation (kW) | Dimensions (L×W×H) (m) | Weight (ton) |

| | 100-150 | 6.0×2.8×3.7 | 18.3 |

| | 150-200 | 6.0×2.8×3.7 | 19.9 |

| | 200-250 | 6.0×2.9×3.7 | 22.1 |

| | 250-300 | 6.0×2.9×3.7 | 23.8 |

| | 300-400 | 6.0×2.9×3.7 | 28.3 |

| | 400-600 | 7.3×3.3×4.2 | 33.5 |

| | 600-800 | 8.5×3.4×4.6 | 37.1 |

| | 800-1000 | 8.5×3.6×5.0 | 45.7 |

| | 1000-1200 | 11.0×3.9×5.2 | 53.2 |

| | 1200-1600 | 11.0×4.1×5.6 | 66.5 |

- No oil system, no complex and expensive oil separator

- Small volume, low noise

- A wide range of heat sources

- Strong adaptability under different working conditions

- Using the latest SRM line technology, higher mechanical efficiency

- Excellent tightness, low failure rate

- Network safety and reliable

- Compact equipment, less floor space, less engineering construction

- Low maintenance cost, easy to operate

- Stable performance, high heat recovery

- Remote control, unattended