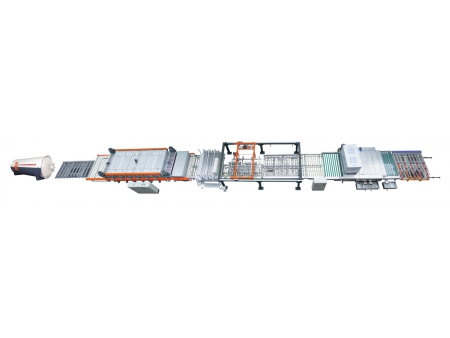

Automatic I.G. Production Line

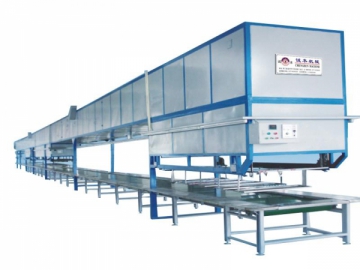

As a professional glass processing machinery manufacturer, we have developed a series of premium IG production equipment for the production of insulating glass. This automatic insulating glass production line is a system that consists of seven sections, including feeding, cleaning, drying, checking, conveying, framing, assembly and lamination. This makes the process methodical, clean and efficient.

Technical Parameter of Automatic Insulating Glass Production Line

1. Power: AC380V, 42kW;

2. Air pressure: 0.6~0.7MPa;

3. Equipment size: 3500*3000*22500;

4. Maximum load:350kg;

5. Minimum glass size: 240*450;

6. Maximum glass size: 2500*3000;

7. Thickness of insulating glass: 16~50mm;

8. Working height:500mm;

9. Conveyor speed:36m/min;

10. Working angle: 6~ 9°.

Features

1. Each of the 7 sections on the vertical insulating glass flat pressing production line, when seated vertically at the same angle, are installed within a laconic structure, making it economical, efficient and easy to maintain.

2. The lamination section (pressing section) ensures the glass and spacer bars will be accurately positioned, and the butyl or other spacer bars will adhere to the glass evenly and firmly.

3. The roll over table on the insulated glass production line turns the vertically positioned insulating glass to a horizontal position.

Configurations

1. TRIO control system with touch screen interface

2. Assembly-in or assembly-out press

3. Automatic glass position system

4. Perfect washing performance of low-e glass

5. Automatic energy saving system

6. Automatic twice pressing for large size of insulating glass

7. Automatically accurate positioning for step insulating glass

18. Automatic positioning and assembly system for three-layer insulating glass processing

| Items | Types | Brand | Made in |

| air-switch | Schneider | China | |

| 24V DC | Meanwell | Taiwan, China | |

| electric relay | Schneider | France | |

| Touch Screen | 10.4 inch TK8100I | Weinview | Taiwan, China |

| Servo Motor & Driver | 0.75 kW | Schneider | France |

| Servo Motor & Driver | 0.4 kW*3 | Schneider | France |

| CPU Module | MC408 | TRIO | British |

| Extended Module | P317/P318 | TRIO | British |

| Frequency converter | 0.4kw | Schneider | France |

| Pneumatic duplex pieces | SMC | Japan | |

| Solenoid valve | AIRTAC | Taiwan, China | |

| Cylinder | AIRTAC | Taiwan, China | |

| Linear slide | HIWIN | Taiwan, China | |

| Planetary reducer | EISELE | Germany |