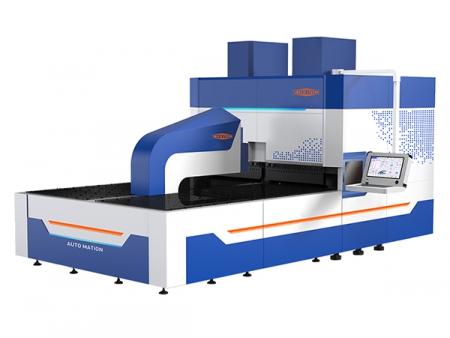

Automatic Spacer Bending Machine

Boza's automatic aluminum spacer bar bending machine is an insulated glass machine designed to bend aluminum spacer bars on insulated glass. The automatic spacer bending can adjust and control the aluminum frame size, and shape automatically using the CNC system; bending the aluminum spacer bars into multiple shapes, such as a triangle, rectangle, regular pentagon, regular hexagon, round, oval and other shapes.

Technical Data

Model: FB-S

Dimensions: (mm) 10,500 (w) × 2,100 (h) × 2,200 (d)

Power supply: AC220 V, 2.5kW, 50Hz

Air pressure: 0.6MPa

Features

1. Errors are smaller than 1.0mm.

2. The butyl glass cement surface is smooth, with no tabs in the bending positions, and the error between bending positions width and the aluminum bar's width is less than 0.3mm.

3. Processing speed test: ≤40seconds/unit for 1000mm×1000mm 9A aluminum bar (automatic stocking time included)

4. Processing database: allows users to set 4 types × 16 sizes × 9,999 pics at the same time

5. Processing range: the CNC spacer frame bender can bend aluminum bars into a rectangular frame.

| Aluminum Bars | Min. size | Max. size |

| once forming frame | 300mm ×300mm | 2000mm ×2000mm |

| combined frame | 5000mm ×2500mm. the error range of each formed aluminum frame is within ±1.5 mm | |

| Irregular frame curved frame | The angle and arc length of aluminum can be adjusted arbitrarily according to the material quality of the aluminum bar. | |

Advanced Design

1. The machine has a special automatic connection design for aluminum bars, and an intelligent steering process away from the joints (connections joints, where two bars are connected).

2. This machine also features an adjustable bending speed. (Fold the curved speed intelligence to regulate)

3. A high-speed, on-end bending function (depending on customer needs) as well as safety devices are equipped on the machine.

4. The automatic aluminum bar connection device does not disturb the operation, and is stable, and reliable, making it safe for continuous operation.

5. The output counter and real-time clock displays the current date and time.

6. An independent bending head is designed with a 6-16mm bending head made of special steel, and is resistant to wear.

7. Automatic sleep functions help the machine save energy.

Operation

1. Except for the start and stop operations, this spacer bar bending machine can be operated using the touch screen.

2. Manual operations are available for all functions, which is helpful for debugging and emergency maintenance.

3. 24 hours, 7 days a week continuous operation is available, with only a normal 4 hour maintenance period each month.

Details of automatic spacer bar bending machine

Related Names

Automatic spacer bending machine | Spacer bar bender | Spacer frame bending machine