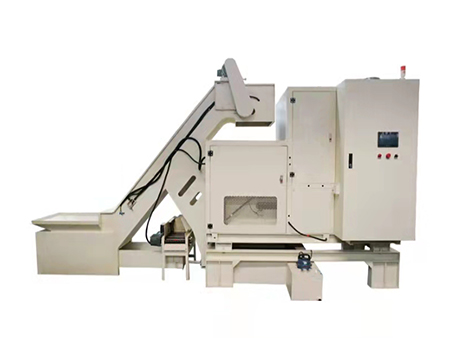

Metal Chip Briquetting Machine

- Aluminum scraps → Aluminum briquettes

- Copper scraps → Copper briquettes

The metal chip briquetting machine is applied in aluminum extrusion factories, steel foundries, aluminum foundries, copper foundries, and machining plants to squeeze scraps of aluminum, steel, cast iron, and copper into briquettes for re-melting, reducing losses during melting, saving energy, and lowering carbon emission. The briquetting press can compress powdered materials (such as iron ore powder and furnace slag powder) and non-ferrous metal scraps into briquettes. The process is cold pressing without the need of warming, additives, or other techniques. During the briquetting stage, cutting fluids and briquettes can be separated so that the fluids can be recycled and the metal chip briquettes remain unpolluted. The briquetting machine reduces scrap volume by up to 40:1.

Technical specifications

| Capacity | 130t | |

| Briquetting objects | Cast iron and steel | ≈2.73kg/pc |

| Copper | ≈3.3kg/pc | |

| Aluminum alloy | ≈1kg/pc | |

| Size of briquettes | ⌀ 120mm x 50-70mm | |

| Capacity per hour | Iron and steel | 393kg/h |

| Copper | ≈475kg/h | |

| Aluminum alloy | ≈120kg/h | |

| Intensity | Chip materials | Briquetted |

| Iron and steel | ≈4.8g/cm³ | |

| Copper | ≈5.8g/cm³ | |

| Aluminum alloy | 1.9g/cm³ | |

| Control system | PLC, touch screen | |

| Total power | ≈20kW | |

| Hydraulic oil | 46/68 anti-wear hydraulic oil | |

| Hopper volume | ≈220L | |

| Power supply | 380V/50HZ | |

| Feed mode | Synchronous feeding vertically and horizontally | |

| Total weight | ≈3000kg | |