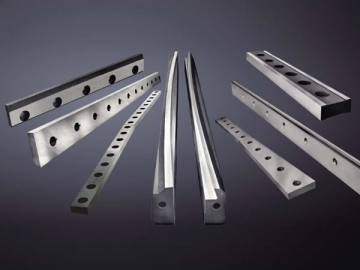

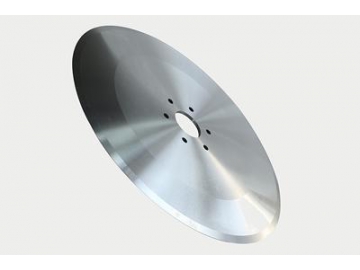

Industrial Blade(Sheet Metal Shear Blade)

Are you getting tired of swapping in and out your industrial blades from time to time? Does your guillotine shear cut poorly? Let HENDLIDA help you out and get the most performance out of your shearing machine. HENGLIDA is a Chinese cutting blade manufacturer. Our shear blades are typically made of T8, T10, 9CrSI, 6CrW2Si, Cr12MoV, H13, LD or HSS.

After heat treating, blades made out of C75 or C65 carbon steel, T8, or T10 maintain a hardness level between HRC57 and HRC59, which makes them suitable for shearing low-carbon, cold-rolled sheets, regular A3 sheet metal, and scrap sheet metal. One major benefit of our carbon steel shear knife is its low price.

Low-alloy steel blades are commonly constructed of 6Crw2sI, 9CrSi, and Cr12MoV, having a hardness range from HRC58 to HRC62. Low-alloy shear knife is specially designed to cut hot-rolled, stainless steel plates of medium and large thickness.

The third type of shear blade is one made of high alloy steel, such as 4Cr5MoSiV1(H13K), 7Cr7Mo2V2Si9(LD), or W6Mo5Cr4V2(6542)H13. High thermal resistance suits the blade for many thick plates shearing applications where high temperature is involved. Not easily affected by annealing, this high-alloy shear knife is particularly suitable for use in hot rolling and hot cutting processes.

Industries where HENGLIDA sheet metal shear blade can be used

Light industry, aerospace, shipbuilding, metallurgy, instruments, electrical equipment, stainless steel hardware, steel building, and furnishing industries.