HD-400A High Speed Paper Food Bag Machine

The HD-400A high speed paper food bag machine is the updated version of HD-400 paper bag making machine. It is ideal for making various kinds of paper bags for both staple food and non-staple food.

Features

1. The automatic paper bag making equipment is applicable for 40-80gsm paper.

2. The bag length can be adjusted through the operation on the human-computer interface.

3. Under the control of PLC, the servo system of the high speed paper food bag machine is capable of controlling the bag length freely within certain scope.

4. Accurate tracking system supports automatic tracking.

5. With variable frequency speed control system, the paper bag machinery can complete gelatinizing, shaping, material feeding, photoelectric tracking, length measuring, cutting, countering, and finished product discharging, automatically.

6. The high speed paper food bag machine can manufacture the paper bag in any length without troublesome changing of gear.

1. Raw Material: 40-80gsm paper

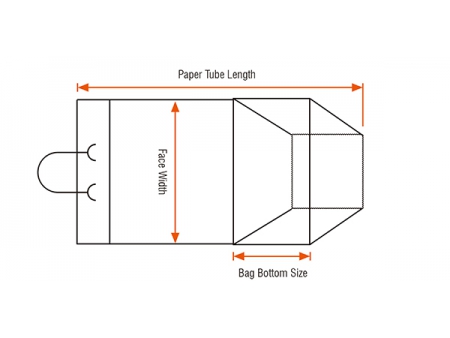

2. Paper Bag Length: 160-440mm

3. Paper Bag Width: 80-250mm

4. Paper Bag Side Width: 20-100mm

5. Paper Roll Width: 230-720mm

6. Production Capacity: 100-400pcs/min. The production speed of the high speed paper food bag machine depends on paper, glue and the skill of worker.

7. Production Capacity for Paper Bag with Thin Film: 80-150pcs/min (Hot-melt adhesive)

8. Max. Paper Roll Dia.: 1200mm

9. Paper Core Diameter: 76mm

10. Total Power: 10kW

11. Glue Type: water-based adhesive, hot-melt glue

12. Machine Weight: 3500kg

13. Power Supply: 380±10V, 50Hz, 3-phase 4-wire

14. Overall Dimensions: 4500mm×1500mm×2100mm

15. Operating Space: 6000×3000×2100mm

16. Operator: 1

- 1.Paper feeding device

2.Magnetic powder braking system

3.Motor for photoelectric correction system

4.Tension controller

5.Hand wheel

6.Glue box

7.Hand lever for glue scraper

8.Gelatinizing wheel

9.Warning light

10.Hand wheel

11.Paper feeding roller

12.Photoelectric tracker - 13.Paper bag forming device

14.Stand for paper bag forming device

15.Hand wheel

16.Hand lever

17.Upper conveying roller

18.Lower conveying roller

19.Cutter

20.Adjustment lever

21.Hand lever

22.Glue tank

23.Hand wheel

24.Glue feeding device

25.Edge folding unit - 26.Bag bottom sticking roller

27.Hub

28.Control box

29.Proximity switch

30.Cutting knife

31.Hand wheel

32.Servo motor

33.Main servo motor

34.Electric appliance box

35.Photoelectric correction system

36.Control box for photoelectric correction system

37.Lubrication pump