Rotary Screw Air Compressor (Electric Bus Air Compressor)

Electric buses are becoming more and more common. A traditional rotary screw air compressor powered by an internal combustion engine does not work on an electric bus, which is why we have developed the MD3 series electric air compressor, which is specially designed to withstand the demanding conditions encountered when operating an electric bus. As an enduring favorite for electric vehicles, this on-board air compressor uses two meshing helical screws to compress the incoming air.

Other desirable features for the car air compressor include a variable speed drive and the air cooling system, ensuring the unit will always run in optimum condition. As a highly automated small air compressor, the unit has been tested to provide safety, reliability, energy saving performances and intelligence through a series of destructive designed tests.

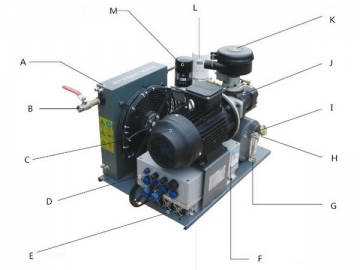

A. Cooling System: A combination of air coolers and oil coolers.

B. Inlet Combination Valve: A Wolkair combination valve is carefully selected for use at the inlet of the car air compressor. The valve automatically opens and shuts off to control the mount of compressed air that is applied to the air brake system.

C. Electric Motor:

Power: 3kw

Certifications: CE Marking

Degree of protection: IP56

Insulation class: F

Energy efficiency rating: IE3

D. G3 Automatic Controller (For electric bus only): Available with CAN&MODBUS

E. Motor Base: Different materials can be used to customize the motor base in various shapes and thicknesses. Popular options include stainless steel bases and a weather tight base.

F. Grade 1 Energy Base

G. Oil Inlets (on both sides of the tank)/Oil Level Sight Glass: Users can fill or observe oil levels from different directions.

H. Oil Temperature Control System: GASCOT patented temperature control technology solves the problem of lubricating oil melting too easily within the on-board rotary screw air compressor.

I. Separator Tank: Designed with various tough terrain conditions in mind, the oil storage tank prevents oil from spilling or rushing out when the electric bus runs on a bumpy road, up and down slopes, or stops with a lurch.

J. Double Screw Mechanism: The rotor system uses two screws to compress the air. This rotary screw assembly is purchased from Wolkair and delivers a high efficiency, reliability, low noise and high resistance to vibration and bumps. A high quality rotor is the reason the MD3 series rotary screw air compressor can achieve a high energy efficiency rating.

K. Air Filter: A specialized large capacity air filter is the well know brand MANN. Made of a highly breathable material, the filter causes a lithe drag to the passing air. The use of an air filtration device also improves the service life of the screw.

L. Oil and Air Separator: A large capacity MANN brand external oil and air separator ensures the cleanliness of the oil and air, allowing for easy maintenance.

M. Oil Filter: The oil filter is also from MANN.

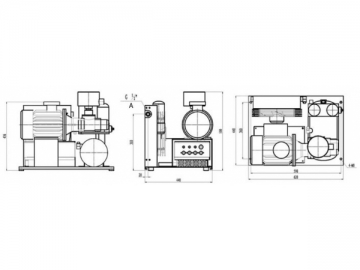

Diagram of Overall Dimensions

A. Air Inlet

Technical Specifications

| Model Code | MD3 | |

| Rated Discharge Pressure (MPa) | 0.8 1.0 | |

| Nominal Volumetric Flow Rate (m3/min) | 0.37 0.32 | |

| Discharge Temperature (℃) | ≤90 | |

| Electric Motor | Rated Power (kW) | 3 |

| Rated Rotary Speed (rpm) | 2870 | |

| Starting Method | Variable Speed Drive, Soft Starter | |

| Voltage (V) | 380 | |

| Frequency (Hz) | 50 | |

| Motion Transmission | Direct drive (with elastic coupling) | |

| Oil Content of Compressed Air | ≤1 | |

| Matched pipe diameter | 1/2 | |

| Dimensions (L×W×H) | 620×440×500 | |

| Cooling Method | Air Cooling | |

| Total Weight | 75 | |

| Level of Noise dB(A) | ≤70 | |

| Power Supply | DC600V (adjustable range: 400-750VDC) | |

| Oil Tank Capacity (L) | ≤3.5 | |