Rotary Screw Air Compressor (Compact Screw Compressor)

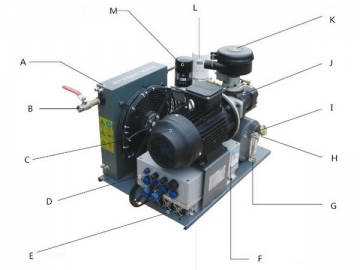

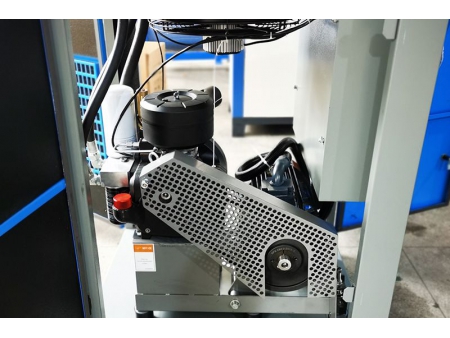

Bigger isn't always better, and small is sometimes a better choice. This screw compressor has a rotary screw mechanism that is built in one piece with a horizontal storage tank to form a compact unit. As a small space-saving machine, it features easy and hassle free installation. Simply connect the rotary screw air compressor to the pipe, plug the unit in, and hit start.

When it comes to quality screw air compressors, customers come to us from all over the world for their small air compressor needs. We offer two models of portable air compressors: one is an economy unit and the other is the standard version with a sound damper.

Designed with noise muting in mind, the MT series screw air compressor delivers an extremely quiet operation even without the use of any sound muting features. As a quiet air compressor, this economy compressor unit can be used under various severe working conditions.

Technical Specifications of MT Series Rotary Screw Air Compressor

| Model Code | Operating Pressurebar | Volumetric Flow (m3/min) | Motor Power (kw/Hp) | Noise dB(A) | Tank Volume (L) | Dimensions (mm) | Outlet Pipe Diameter G Weight (kg) |

| 7~10 | 0.8~0.6 | 5.5/7.5 | 66 | 230 | 1600*500*1000 | 3/4" 352 | |

| 7~10 | 1.1~0.8 | 7.5/10 | 68 | 230 | 1600*500*1000 | 3/4" 359 | |

| 7~10 | 1.6~1.4 | 11/15 | 68 | 230 | 1600*650*1200 | 3/4" 397 | |

| 7~10 | 2.5~2 | 15/20 | 73 | 500 | 1600*680*1450 | 1" 518 | |

| 7~10 | 3~2.7 | 18.5/25 | 73 | 500 | 1600*680*1450 | 1" 523 | |

| 7~10 | 3.6~3.2 | 22/30 | 73 | 500 | 1600*680*1450 | 1" 563 |

**Note: The above models are for reference only. We can produce customized rotary screw air compressors for our customers.

Functions/Protections

| Remote control/On-site control | √ |

| RS-485 communication, supporting MODBUSRTU protocol | √ |

| Linkage mechanism/Computer-based centralized control | √ |

| Oil filter (time set-point entry) | √ |

| Air filter (time set-point entry) | √ |

| Oil and air separator (time set-point entry) | √ |

| Lubricating oil(time set-point entry) | √ |

| Lubricating grease (time set-point entry) | √ |

| Belt (time set-point entry) | √ |

| Motor protection (overload, phase loss, imbalance, over-voltage, under-voltage) | √ |

| Blower overload protection | √ |

| Low temperature protection | √ |

| Discharged air over-temperature protection | √ |

| Screw reverse rotation protection | √ |

| Air supply over-pressure protection | √ |

| Sensor failure protection | √ |

VI. Display, Alarm, Interlock (power failure protection)

| Items | Display | Alarm | Interlock | Note |

| Oil filter (time set-point entry) | √ | √HA | ||

| Air filter (time set-point entry) | √ | √HA | ||

| Oil and air separator (time set-point entry) | √ | √HA | ||

| Phase order protection | √ | √ | √ | |

| Discharge end temperature | √ | √HA | √ | |

| Discharge end pressure | √ | |||

| Thermocouple failure | √ | √ | √ | |

| Startup Timeout | √ | √ | √ | |

| Fan failure | √ | √ | ||

| Main unit failure | √ | √ | √ | |

| Air supply temperature | √ | |||

| Alarm Record | √ | |||

| Operating Time | √ | |||

| Integrated Control | √ |