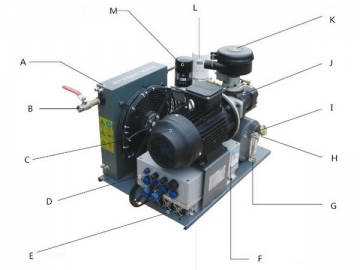

Rotary Screw Air Compressor (Direct Drive Screw Compressor)

The direct drive coupler is a unique asset on this rotary screw air compressor, as opposed to the belt drive that is installed on most Woyo screw compressors. A major benefit of a direct drive versus a belt drive includes the fact there are fewer parts, costs less and has a simpler design.

The HSD series rotary screw air compressor is specially constructed for industrial purposes with a speed rate of 3,000RPM. With a GHH patented oiled screw as the rotor, the oil injected screw compressor runs quietly and smoothly. It can withstand continuous use, due to the great lubrication. The excellent durability rate will also save consumers operation costs in the long run.

Each HSD series direct drive screw compressors have been built to strict standards in regards to design, production and tests. We also provide quality after-sales services for each air compressor we sell. No matter what model customers choose, a high quality is guaranteed.

Features

1. A patented inlet valve coupled with a PLC system allows the compressor to control the air supply amount to the changing demands of your industrial processes. The unit automatically shuts off when no air has entered the valve within a 20 minute period, saving electricity.

2. A convenient direct drive enables a nearly 100% motion transmission efficiency, which reduces energy loss during transmissions, which leads to saving operating costs.

3. Large rotors are sufficiently supported by large bearings. A good lubrication ensures a smooth rotation, creating less noise than a traditional oil-free unit.

4. Less wear on the parts prolongs the service life.

Technical Specifications

| Model No. | Operating Pressure (bar) | Volumetric Flow Rate (m3/min) | Motor Power (kw/Hp) | Noise dB(A) | Dimensions (mm) | Weight (kg) /Outlet Pipe Diameter G | Dimensions (mm) |

| 7/8/10 | 10.3/9.8/8.3 | 55/75 | 72 | 1800×1230×1450 | 1300/1-1/2" | 2200×1230×1450 | |

| 7/8/10 | 13.6/12.6/11.6 | 75/100 | 75 | 2000×1450×1450 | 1900/2" | 2400×1450×1450 | |

| 7/8/10 | 16.8/16.4/13.9 | 90/120 | 76 | 2000×1450×1450 | 2000/2" | 2400×1450×1450 | |

| 7/8/10 | 20.8/20.6/17 | 110/150 | 76 | 2400×1500×1670 | 2400/2-1/2" | 2800×1500×1670 | |

| 7/8/10 | 24.2/23/20.3 | 132/180 | 76 | 2400×1500×1670 | 2500/2-1/2" | 2800×1500×1670 | |

| 7/8/10 | 29/28/25 | 160/215 | 78 | 3150×1720×1930 | 4200/2-1/2" | 3550×1720×1930 | |

| 7/8/10 | 45/42.5/40 | 250/340 | 78 | 3450×1980×2150 | 5500/DN80 | 3850×1980×2150 |

**Note: The above models are for reference only. Customized options are available.

Functions/Protections

| Remote control/On-site control | √ |

| RS-485 communication, supporting MODBUSRTU protocol | √ |

| Linkage mechanism/Computer-based centralized control | √ |

| Oil filter (time set-point entry) | √ |

| Air filter (time set-point entry) | √ |

| Oil and air separator (time set-point entry) | √ |

| Lubricating oil(time set-point entry) | √ |

| Lubricating grease (time set-point entry) | √ |

| Belt (time set-point entry) | |

| Motor protection (overload, phase loss, imbalance, over-voltage, under-voltage) | √ |

| Blower overload protection | √ |

| Low temperature protection | √ |

| Discharged air over-temperature protection | √ |

| Screw reverse rotation protection | √ |

| Air supply over-pressure protection | √ |

| Sensor failure protection | √ |

VI. Display, Alarm, Interlock (power failure protection)

| Items | Display | Alarm | Interlock | Note |

| Oil filter (time set-point entry) | √ | √HA | ||

| Air filter (time set-point entry) | √ | √HA | ||

| Oil and air separator (time set-point entry) | √ | √HA | ||

| Phase order protection | √ | √ | √ | |

| Discharge end temperature | √ | √HA | √ | |

| Discharge end pressure | √ | |||

| Thermocouple failure | √ | √ | √ | |

| Startup Timeout | √ | √ | √ | |

| Fan failure | √ | √ | ||

| Main unit failure | √ | √ | √ | |

| Air supply temperature | √ | |||

| Alarm Record | √ | |||

| Operating Time | √ | |||

| Integrated Control | √ |