Optional Waterjet Accessories

Tailored Waterjet Solutions with a multitude of accessories

- Abrasive Metering Feeder

-

Operating pressure:0.2MPa

Abrasive capacity:170LThe DAADS abrasive metering feeder is designed to store abrasive materials and automatically convey them to the hopper. The equipment features easy operation, greatly improving the productivity of the waterjet cutting system, and is maintenance free.

The 170L abrasive capacity can supply a waterjet cutting machine as it works for 500 to 800 minutes. The system comes with precise level sensors which can automatically monitor the amount of materials in the chamber and sound an alarm if it becomes too low.

-

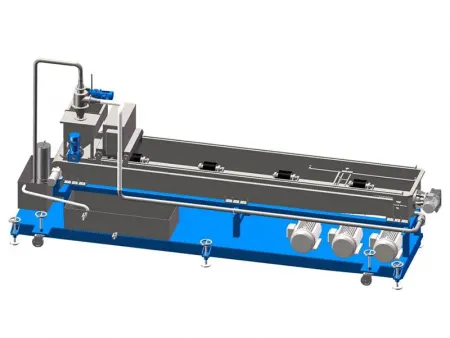

- Abrasive Removal System

-

Bladder Capacity:410L

Abrasive Removal rate:38kg/minThe Xtractor abrasive removal system is designed for removing and collecting waste abrasives. It features a water and abrasive slurry separation method. It can greatly improve the abrasive removing efficiency and minimizes labor costs.

Each Xtractor abrasive removal system adopts an independent unit design and features a compact size that is easy to operate. Its water recycling system can effectively reduce water consumption. It has a hydraulic discharge mechanism at the bottom.

- Chiller System

-

Power:3.5~7.4Kw

Cooling capacity:6000~17200kcal/hThe chiller system was developed to control the temperature of the water used by the waterjet cutting machine. It can effectively prolong the service life of high-pressure parts and reduces the water consumption of the waterjet cutting machines in general.

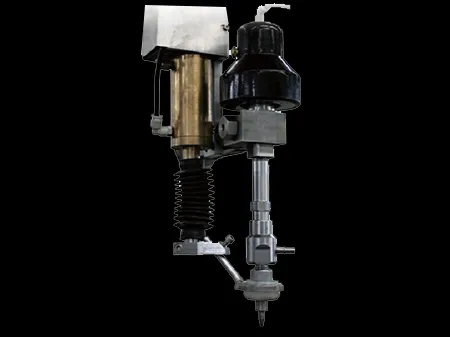

- Height/Crash Sensor

-

Air source pressure:0.6Mpa

Stroke:50mmThe DAE height sensor is installed to control the distance between the cutting head and workpiece to reduce the potential for broken nozzles. It also can reduce the workload and occurrence of human errors of the operator.