Waterjet Cutting Head

Dardi provides 5-axis cutting heads which provide high precision cutting with high speed and reliability. They are the culmination of many years of improvements and have been praised by hundreds of clients who have benefited from their advantages. The productivity of our waterjet cutting head is 30% to 200% higher than that of traditional waterjet cutting heads. Each of our AB 5-axis cutting heads is manufactured to meet the requirements of Q/32015 ADD004-2012 standards.

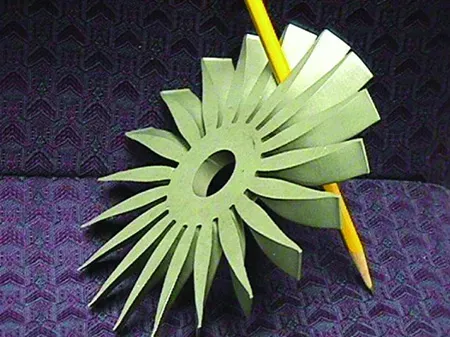

- X-5 AB 5-Axis Cutting Head

-

The X-5 AB 5-axis cutting head was developed for small angle and vertical cutting. It is particularly suited for stone and ceramic tile cutting. This cutting head is equipped with a specially designed bevel edge control mechanism (AB 5-axis) and able to cut the stone or ceramics with beveled edges in the opposite direction of cutting. It can realize seamless stitching of stone and ceramics to cut down on the amount of grinding and polishing.

Features- The cutting head is controlled by intelligent cutting software and can automatically cut scanned graphics. It supports automatic image stitching, module rendering and shading, so you can realize various designs as you like.

- The cutting software supports a graphic disassembly and layout so as to improve the efficiency of graphic drawing. The trepanning function helps you minimize material waste.

- It uses diamond waterjet orifices and a durable sand pipe to avoid frequently replacing accessories so as to decrease the maintenance cost and improve production efficiency.

- The cutting head adopts an ESA CNC system and IGEMS 3D CAD/CAM software which features powerful functions and are easy to use.

Parameters- Beveling angle (B-axis): ±10°

- Angle from perpendicular(A-axis): ±10°

- Positioning accuracy: 0.1mm±0.15mm

- Driving method: servo motor

- Control method: digital control

-

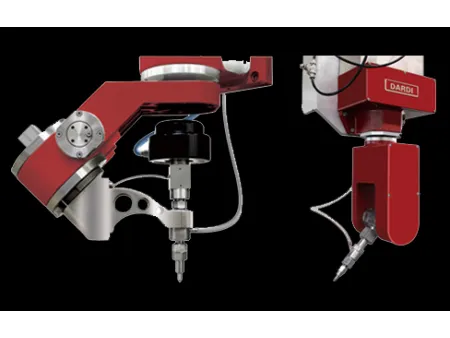

- X-5 AC 5-Axis Cutting Head

-

The X-5 AC 5-axis cutting head effectively resolves cutting problems faced by traditional waterjet cutting machines. It supports large angle bevel cutting and 3D cutting. It can quickly and easily complete taper-free cutting, bevel cutting, chamfering, surface trimming, and more.

Features- It can automatically modify the angle using the convenient CNC control system.

- The C-axis is equipped with a harmonic drive which features high positioning accuracy and low backlash.

- There is a rotary joint on the C-axis to prevent vibration from transferring to the cutting head and eliminate the errors caused by the oval hole of the sand pipe.

- The on/off valve is lightweight, small in size, and features rapid reaction speed.

- The angle of hypotenuse is less than 1° during the vertical cut.

ParametersCutting Angle A-axis ±60° or ±90° C-axis ±360° Positioning Accuracy ±60°