Automated Assembly System

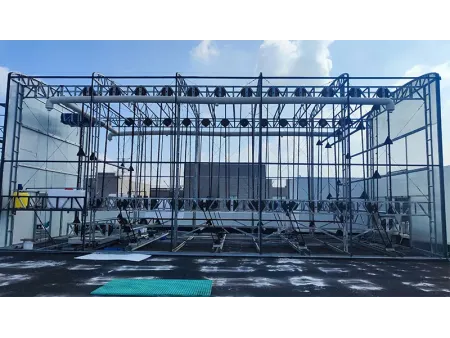

Brady provides automated assembly solution for LED lights, electronic products and other precise components. Our automated assembly solutions designed for high working efficiency, production capacity and consistent quality based on advanced automation technology modules including robotics assembly, automatic soldering, screw driving, dispensing and inspection. Production process and working station are all customized as your requirements, aim at minimize your labor cost and manufacturing cycle time.

No matter which type luminaire or electronic product you need, low or high productivity you asked for, we are pleased to assist you in realizing what you want.

-

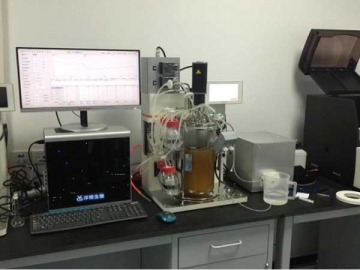

- Robotics

- We adopt robot technology and motion control system to achieve automatic material feeding and handling, which improves the overall production efficiency.

-

- Soldering

- Using Z/Y1/Y2/Z/R five-axis motion control, the fully automatic soldering robot can easily solder complex components. It can also realize automatic soldering wire feeding.

-

- Fastening

- Precision screw driving robot can complete screw fastening in an efficient way during the mass production. Other functions can also be integrated in this robot like vision inspection.

-

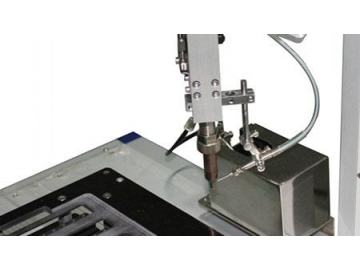

- Dispensing

- Our automatic dispensing equipment can be used for single point dispensing and continuous dispensing. Large format X-Y table dispensor and precise robotic dispensor are avaliable.

-

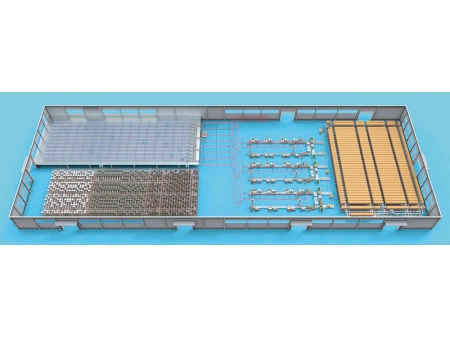

- Placement

- After dispensing, the placement can be made by the automatic pick and place machine, with an accuracy of 0.1mm.

Our engineering team is devoted to assembly solution for 20 years. With rich knowledge and experience in automation technologies, we focus on optimizing production process and improving versatility of our automated assembly line and equipment. As a result, you are allowed to manufacture products in different types using only one equipment, which reduced your initial investment.

Because of stability, efficiency and utility, Brady automation solution gains recognition from many well-known companies, such as Philips, Huawei, TOSPO, BYD, FSL, TCL, Flextronics, and so on. Until now, our global business has covered many contries and areas, including UK, Canada, Korea, Russia, India, Japan, Singapore, Vietnam, Thailand, Malaysia, Indonesia, Philippines, Mexico, Morocco, etc.

We have a modern factory with ISO 9001 certification. All production processes, such as processing of main parts, assembling and testing of the whole machine, are completed in our own factory, so we are able to flexibly privde you customization service based on your needs. We can also better control the quality, production duration and provide competitive prices.

Based on years of experience, we have developed three automatic production lines for LED industry, namely, LED tube light automated assembly equipment, LED light bulb assembly production line and LED down light assembly production line. You can get detailed information from the links below.

- First, we will confirm your production needs and get the actual product samples. Our Engineering Department will set up a special group to analyze the internal structure of your products and provide preliminary SYSTEM plan and design drawings. In this procedure, you can ask any questions about the plan, and the project group will answer or revise the plan.

- Second, after defining the final plan, we will sign the contract, and our special group will issue drawings to the production department to start production.

- Third, after the assembly is completed, the whole line will be debugged and tested to make sure it runs normally and meets your customized requirements.

- Last, we will deliver the system to you. After arriving at your location, the after-sales personnel of our company will assemble and debug the system again. Then, the assembly system can be put into production.

We provide one-year warranty for all our equipment and lifelong technical support services.