Liquid Steel Ladle Before Pouring To Tundish of Continuous Casting System

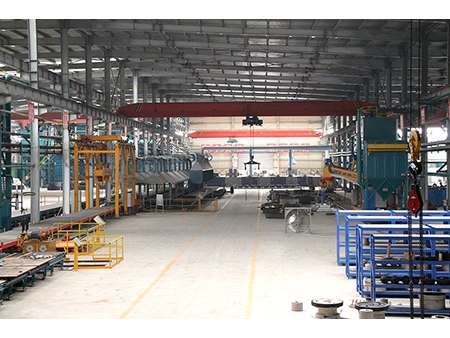

Liquid steel ladle before pouring to tundish is an important part of the continuous casting machine, which is made up of swivel arm, supporting base, basic frame, transmission device, lubrication system and control system. It is mounted on the reinforced concrete base. The liquid steel ladle moves alternatively on the rotating turret. The steel ladle full of liquid steel on the other side rotates to the casting position when one steel ladle is empty. With two ladles’ alternating operating, the continuous operation of the the continuous caster is ensured for continuous pouring. New Anjie produced liquid steel ladle turret weights between 5tons to 60tons. Certainly, we can customize it based on your demands if the weight is beyond this range.

This turret supports the steel ladle. The hydraulic system of swivel arm maintains the steel ladle horizontal, having lifting function as well. Besides, the weighting sensor is added in this equipment to monitor the weight of the steel ladle timely. Transmission mechanism adopts variable frequency alternative current motor as the power system. Our liquid steel ladle turret equips an emergency response mechanism to guarantee the operator’s safety under emergency.