Metal Processing

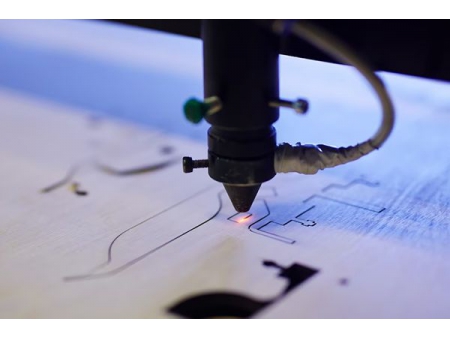

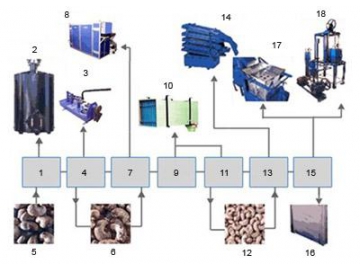

Oxy-hydrogen machines have been used with billet cutting machines since the early 1960s, but in the last decade, we have further developed our oxy-hydrogen generators, carbon cleaning machines, oxy-hydrogen flame cutting machines, and oxy-hydrogen gas welding equipment to apply to other metal processing and heavy machinery in the chemical and petrochemical, aerospace, automobile and boiler, panel processing, patternmaking, and hydropower industries.

Cutting Characteristics of Oxy-Hydrogen Gas

1. Meets different flame requirements such as a neutral flame, carbonizing flame and oxidizing flame.

2. Leaves cutting surface smooth and flat with no residue or dregs.

3. Narrow cutting edge means the clean technology machine won't waste material, there's a smaller heat affected zone and no deformation.

4. No hidden issues such as burning back, ensuring cutting safety.

5. Minimal pollution makes it more environment friendly.

6. Economically efficient, saving you 70-75% more than acetylene gas and 40% more than propane gas.

Range of Application

1. Suitable for low, middle carbon steel and low-alloy steel with the thickness under 300mm.

2. Compatible with manual, semi-automatic and automatic cutting machines.

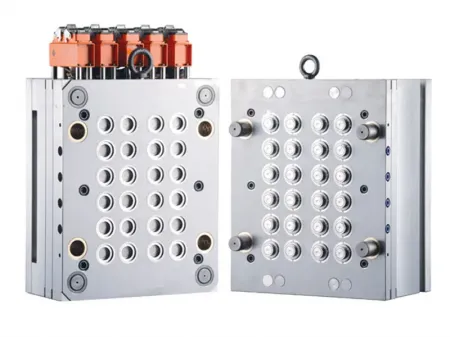

Recommended Products