Mold Holder and Frame for Rotary Blowing Mold

The design and production of blow mold frames hinge on key factors like the shape, size, and quantity of finished bottles, alongside the machine’s production efficiency and durability. Our focus is clear: deliver high-quality plastic bottles with precision and reliability.

A mold frame is a critical component of a blow molding machine, essential for producing high-quality bottles. It supports the blow mold, ensuring a smooth and stable molding process. Crafted from high-strength forged steel with support components made from durable cast iron, our frames are built for longevity and reliability.

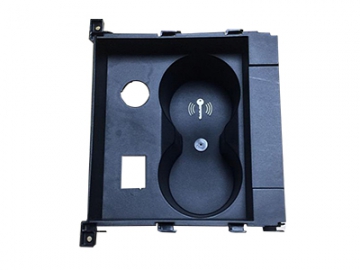

The mold carrier is mounted on the compaction base, positioning the mold precisely at the center of the columns. During compaction, it securely holds the mold, mold ring, and base in place.

Mold frames and mold carriers are vital for rotary blow molding machines. The mold frame acts like a mechanical arm, fixed to the equipment, with its “claws” designed to hold the mold carrier firmly in place.