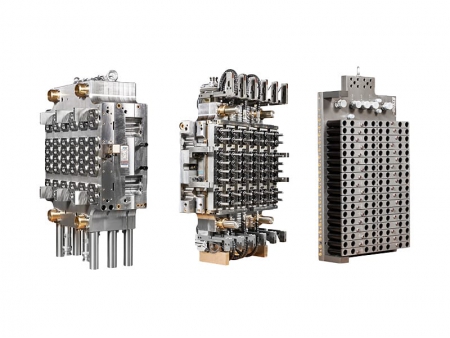

Mold Shell for PET Blowing Mold

Known as the backplate, the mold shell is the cornerstone of rotary PET blow molding, engineered for rapid cooling. This vital component keeps molds at optimal temperatures during operation, preventing damage from heat buildup and ensuring flawless bottle formation. For large-capacity bottles, we seamlessly integrate the mold shell with the mold itself, delivering unmatched performance and precision.

The mold shell, often called the backplate, is the heart of rotary PET blow molding, driving molding efficiency, bottle quality, and equipment longevity. Its critical role shines through in these key areas:

The mold shell, also known as the backplate, is a critical component tailored specifically for PET blow molding, delivering precision and efficiency in crafting top-quality PET bottles. Its sophisticated design ensures exact shaping and molding, producing consistent, defect-free bottles. This precision is essential for businesses striving to uphold exceptional quality and uniformity across their production lines.

The mold shell, or backplate, is mounted on the mold’s rear, serving multiple key functions. It reinforces mold thickness, facilitates water transfer for cooling, and provides secure mounting to the machine’s platen.

A standard feature in blow molding machines, the backplate is indispensable. Its primary role is to manage heat by circulating cold water through integrated channels, rapidly cooling the mold to prevent damage and ensure high-quality bottle formation.