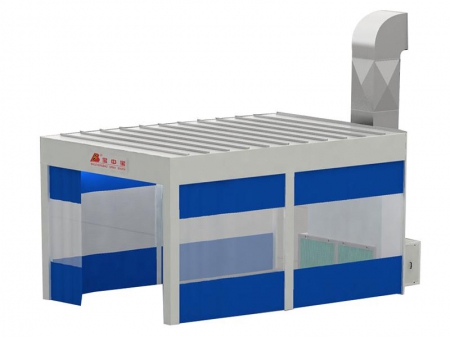

6300 Prep Station

Request a Quote

List of Configurations

| Product Name | Prep Station | |||||

| Product Model | BZB-6300 | |||||

| Product Configuration and Technical Parameters | Internal Dimension (mm) | 6400×4000×2650 | External Dimension (mm) | 7650×4106×3150 | Total Power | 6.5kW |

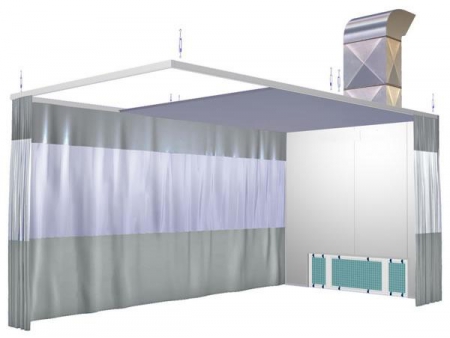

| Cabin System | 1. Ceiling: At the top of our 6300 prep station, the plenum chamber adopts the cold-rolled steel plate which has gone through such processes as bending, spraying, and molding. The roof panel utilizes the galvanized steel plate, which is hoisted in use of steel rope. 2. Front and Two Sides: The flexible PVC curtain is used to slide on the scheduled aluminum alloy guide rail. 3. Back: The EPS steel skin panel of 50mm thick is placed on the rear side of the wall. 4. No basement | |||||

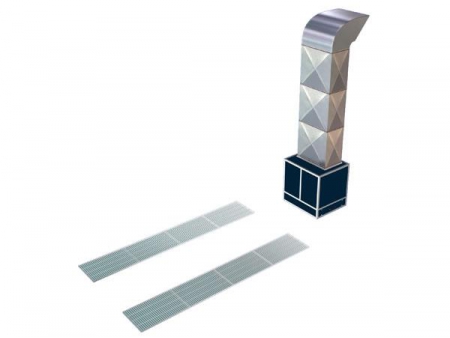

| Circulation System | 1. The air is exhausted through the back. 2. Centrifugal Fan: The YDW series double-inlet centrifugal fan is made in use of Siemens technology. This fan is formed of compression molded galvanized plate. It has such striking advantages as great air quantity, low noise, and high temperature resistance. Additionally, it is made by a fan specialist. Its specifications can be seen as follows. Model : YDW-5.6S Air Capacity: 15,000m3/h Total Pressure: 800Pa Rotational Speed: 900rpm Power: 5.5kW Quantity : 1 set 3. Exhaust Cabin: The cabinet is assembled by coated steel plate. Its framework is made of section bar. The structure is solid, elegant, and easy for maintenance. | |||||

| Air Purification system | 1. The high-quality filter screen is imported from Italy. It has multiple layers, which is placed at the bottom of the plenum chamber, and supported by roof mesh. 2. The roof mesh is constructed from C-shaped steel with strong corrosion resistance. It is replaced easily, and can effectively catch the dust particle with its diameter of over 5μm. | |||||

| Environmental System | On the back of the cabin , there is the fiberglass filter felt for reducing dust fog, thus providing a favorable working environment. | |||||

| Lighting System | 1. Lighting sets are mounted on the side of the ceiling. 24 pieces of 36W Philips tubes allow the light in the cabin to be soft, uniform and brilliant. 2. The ballast is dedicated for our 6300 prep station. It possesses reliable performance and long lifespan. | |||||

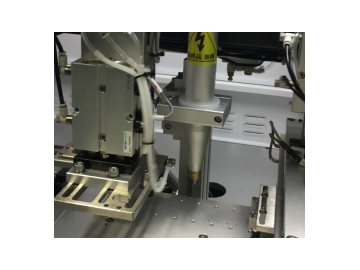

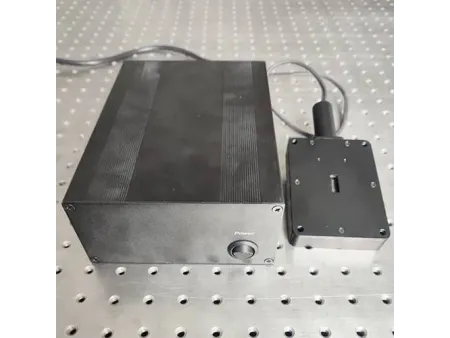

| Control System | 1. This control system is formed by a group of exceptional-quality electronic components. By setting up for only once, all operational processes can be completed. 2. The main circuit gives all kinds of protection, such as excess current, excess load, short circuit, phase failure, and some others. This system also comes with the polisher switch, illumination switch, emergency stop switch, and the failure warning system, among others. | |||||

Related Names

Auto Paint Spray Booth | Metallic Car Paint Room | Limited Finishing Prep Station

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos