Rotary Spray Drying Atomizer

Request a Quote

Description

The rotary spray drying atomizer should ensure the uniform size of the fog drops so that it can produce powder which can meet the standards and requirements. The selection of atomizer is decided by the raw material features and specification of the product to be dried. Normally, we give priority to rotary spray drying atomizer because of the better flexibility and easy operation.

The rotary spray drying atomizer is suitable for raw material easy to be wear and tear. It can realize rapid material feeding without blocking. This product can adopt low pressure material feeding system of which the rotation speed can be easily adjusted. So the fog drop size can be controlled.

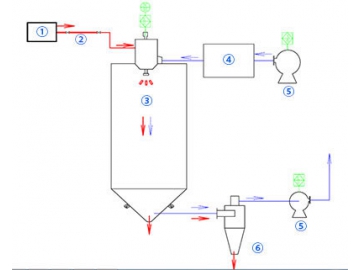

Three kinds of atomizer used in industrial production:- Rotary spray drying atomizer: centrifugal energy caused atomization

- Pressure nozzle atomizer: pressure energy caused atomization

- Two-fluid nozzle atomizer: kinetic energy caused atomization

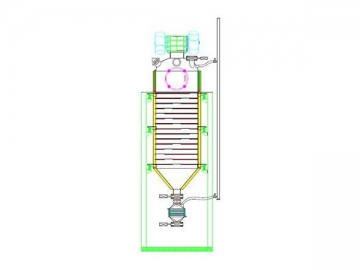

| Spray type | High speed rotary atomizer | ||||

| Atomizer speed (r/min) | 25000 | 18000 | 16000 | 12000-13000 | 11000-12000 |

| Atomizing diameter (mm) | 50 | 102 | 108 | 180-210 | When the water evaporation is over 2000 kg/h, the atomizing diameter is decided according to process requirements. |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos