Progressive Cavity Pump

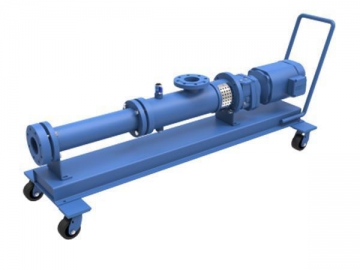

Cavity pump / PC pumps / PCP Systems

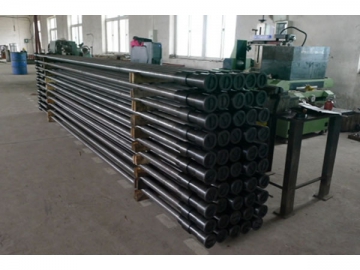

Progressive cavity pumps or PC pumps are widely used in oil field applications around the world. Our company has been committed to the research and development of screw pumps and their accessories for many years. We have successfully produced more than 50 kinds of screw pumps since our inception, in displacement ranges from our GLB20 to GLB3000, and with well depths over 2300m.

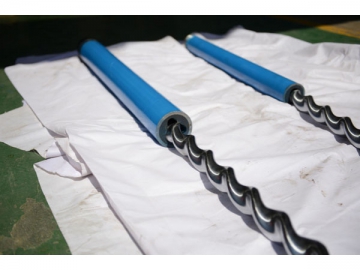

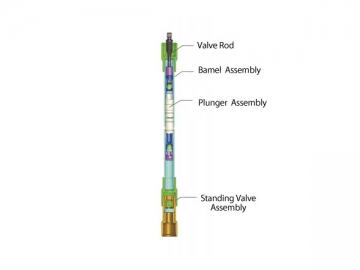

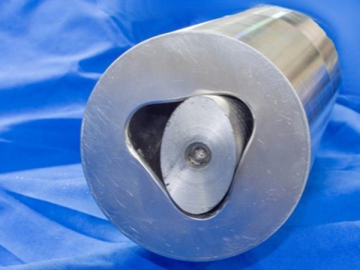

PC pumps are positive displacement pumps. With minimal moving parts and no valve or complicated flow passages, the oil flow is smooth with almost no disturbances and the displacement is uniform. The steel rotor rolls and slides on the surface of the stator rubber bushing, which effectively prevents sand or other abrasive substances from damaging the pump. These PC pumps are suitable for extracting high viscosity crude oil, high wax content oil, high sand content oil and high gas content oil.

Features:

1. Thanks to its simple design, the PC pump has a smaller initial investment, compared with traditional oil extraction equipment, it can reduce costs by 40%.

2. In terms of oil extraction, the efficiency of our PC pump is 3-4 times higher than that of other oil extraction equipment. Compared to direct-drive motors, it is 30%-50% more energy-efficient.

3. The pump is easy to operate. The operator only needs to put the dedicated tools under the well and connect the appropriate tools, the tubular column and the bolt support to the devices on the ground.

4. The subsurface progressing cavity pump is virtually maintenance-free. You only need to maintain the surface drive and change wearable parts periodically.

We have four driving head devices for these PC pumps, belt gear reduction transmission (horizontal), gearless transmission (vertical), direct drive motor gearing and eccentric test gearing.

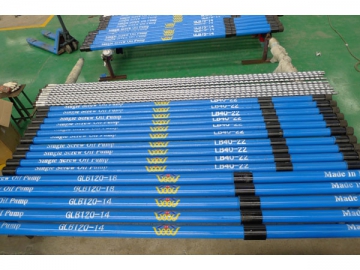

GLB120-14 and rotors ready for delivery to Djakarta!

Technical Parameters:

PC Pump Setting Parameters

There are single head PC pumps for ordinary crude oil extraction, high temperature PC pumps adapted to 170 degree and bimetal type for 350 degree oil handling, hollow rotor PC pumps applied to heating pump and flushing, uniform thickness PC pumps suitable for depths over 1800m or extraction needs of crude oil containing high amounts of hydrogen sulfide, high hydrocarbon, high gas physical properties and special types for CBM drainage gas.

| Setting depth(m) | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| Lifting distance (mm) | 550 | 650 | 750 | 850 | 950 | 1100 | 1200 | 1300 |

| Model | Length (mm) | Maxi. Diameter (mm) | Rotor screw (in) | Stator upper screw(in) | Stator lower screw(in) | Rod rate (rpm) | Theoretical dairy flow(m3/d) | Applicable tubing(in) | Sucker rod(in) | Head(m) |

| GLB10/35 | 2940 | 90 | 15/16" | 2-7/8" | 2-7/8" | 60-150 | 1-4 | ≥73 | 7/8" | 1000-1400 |

| GLB28/40 | 3650 | 90 | 1-3/16" | 2-7/8" | 2-7/8" | 60-150 | 3-6 | ≥73 | 7/8" | 1200-1600 |

| GLB40/12 | 1550 | 90 | 1-3/16" | 2-7/8" | 2-7/8" | 60-150 | 4-9 | ≥73 | 7/8" | 600-800 |

| GLB40/14 | 2200 | 90 | 1-3/16" | 2-7/8" | 2-7/8" | 60-150 | 4-9 | ≥73 | 7/8" | 400-600 |

| GLB40/21 | 2330 | 90 | 1-3/16" | 2-7/8" | 2-7/8" | 60-150 | 4-9 | ≥73 | 7/8" | 700-1000 |

| GLB40/42 | 4670 | 90 | 1-3/16" | 2-7/8" | 2-7/8" | 60-150 | 4-9 | ≥73 | 7/8" | 1200-1800 |

| GLB50/21 | 2380 | 90 | 1-3/16" | 2-7/8" | 2-7/8" | 60-150 | 5-10 | ≥73 | 7/8" | 700-1000 |

| GLB75/14 | 2140 | 90 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 6-15 | ≥73 | 7/8" | 400-600 |

| GLB75/21 | 2200 | 108 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 6-15 | ≥73 | 1" | 700-1000 |

| GLB75/40 | 4410 | 108 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 6-15 | ≥73 | 1" | 1200-1600 |

| GLB120/18 | 3000 | 108 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 10-25 | ≥73 | 1" | 500-800 |

| GLB120/21 | 2932 | 108 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 10-25 | ≥73 | 1" | 700-1000 |

| GLB120/27 | 4428 | 108 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 10-25 | ≥73 | 1" | 800-1000 |

| GLB120/36 | 5865 | 108 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 10-25 | ≥73 | 1" | 1100-1400 |

| GLB120/40 | 5900 | 108 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 10-25 | ≥73 | 1" | 1200-1600 |

| GLB165/35 | 5650 | 114 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 14-36 | ≥73 | 1" | 900-1300 |

| GLB190/33 | 5650 | 117 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 15-40 | ≥73 | 1" | 900-1300 |

| GLB200/27 | 5650 | 114 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 17-42 | ≥73 | 1" | 800-1000 |

| GLB300/21 | 4850 | 114 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 25-60 | ≥73 | 1" | 700-1000 |

| GLB300/26 | 6000 | 114 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 25-60 | ≥88.9 | 1" | 700-1000 |

| GLB300/33 | 6200 | 117 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 25-60 | ≥88.9 | 1" | 800-1200 |

| GLB420/20 | 4820 | 117 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 35-70 | ≥88.9 | 1" | 700-1000 |

| GLB500/14 | 3380 | 117 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 40-80 | ≥88.9 | 1" | 600-800 |

| GLB500/21 | 5060 | 117 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 40-80 | ≥88.9 | 1" | 700-1000 |

| GLB600/18 | 7122 | 117 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 85-130 | ≥88.9 | 1" | 500-900 |

| GLB230/2-30 | 6200 | 117 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 20-50 | ≥88.9 | 1" | 900-1200 |

| GLB450/2-24 | 6520 | 117 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 39-97 | ≥88.9 | 1" | 700-1000 |

| GLB800/2-16 | 5020 | 117 | 1-9/16" | 3-1/2" | 2-7/8" | 60-150 | 70-173 | ≥88.9 | KG36" | 500-700 |

| GLB800/2-24 | 7120 | 117 | 1-9/16" | 3-1/2" | 2-7/8" | 60-150 | 70-173 | ≥88.9 | KG36" | 700-900 |

| GLB1200/2-16 | 6640 | 117 | 1-9/16" | 3-1/2" | 2-7/8" | 60-150 | 103-260 | ≥88.9 | KG36" | 600-800 |

| GLB1400/2-16 | 7420 | 117 | 1-9/16" | 3-1/2" | 2-7/8" | 60-150 | 120-302 | ≥88.9 | KG36" | 600-800 |

| GLB1600/2-14 | 7420 | 117 | 1-9/16" | 3-1/2" | 2-7/8" | 60-150 | 138-345 | ≥88.9 | KG36" | 500-700 |

| GLB1800/2-14 | 7470 | 117 | 1-9/16" | 3-1/2" | 2-7/8" | 60-150 | 155-388 | ≥88.9 | KG36" | 500-700 |

| GLB2500/2-8 | 7470 | 117 | 1-9/16" | 3-1/2" | 2-7/8" | 60-150 | 216-540 | ≥88.9 | KG36" | 400-600 |

| GLB3000/2-8 | 7680 | 117 | 1-9/16" | 3-1/2" | 2-7/8" | 60-150 | 260-648 | ≥88.9 | KG36" | 400-600 |

| GLB4000/2-6 | 7680 | 117 | 1-9/16" | 3-1/2" | 2-7/8" | 60-150 | 430-1080 | ≥88.9 | KG36" | 400-600 |

| GLB75-47/K | 5465 | 108 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 6-15 | ≥88.9 | 1" | 1400-1800 |

| GLB120-40/K | 5900 | 108 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 10-25 | ≥88.9 | 1" | 1200-1600 |

| GLB165-35/K | 5650 | 117 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 14-36 | ≥88.9 | 1" | 1100-1400 |

| GLB300-21/K | 4850 | 117 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 25-60 | ≥73 | 1" | 700-1000 |

| GLB40-21/GW | 2330 | 90 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 4-9 | ≥73 | 7/8" | 700-1000 |

| GLB75-21/GW | 2200 | 108 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 6-15 | ≥73 | 7/8" | 700-1000 |

| GLB120-21/GW | 2932 | 108 | 1-3/8" | 3-1/2" | 2-7/8" | 60-150 | 10-25 | ≥73 | 7/8" | 700-1000 |