Injection Production Integral Subsurface Pump

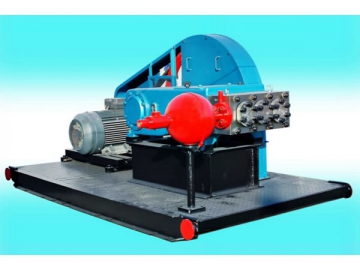

Oil well pump/ Plunger pump/ Injection pump

The injection production integral subsurface pump is designed for oil wells with water content up to 90%, salt content of 18000mg/l, CO2 content of 12% and sulfur content up to 7%. It can also be used for sand drainage in horizontal wells whose sand content is up to 20% (volume ratio). It can carry out steam injection without moving the pipe column and realize the circulating production of steam injection and oil extraction.

Effective Steam Inject

The steam injection method of oil extraction is designed to feed heat insulated tubing string into oil-wells and then inject steam into the oil reservoir. The heat insulated tubing string is then pulled out after soaking, and then loaded into the flow string and pumping unit. Injection integrated oil-well pump can overcome weaknesses in existing technology effectively to achieve the goal of efficient oil production by steam injection.

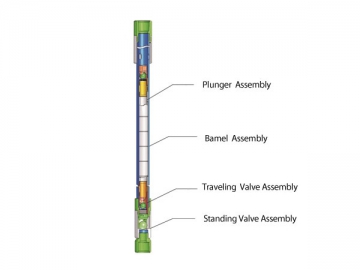

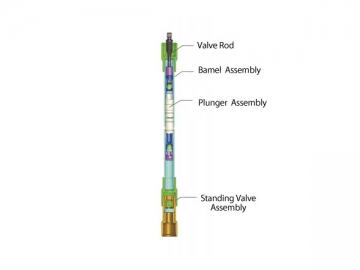

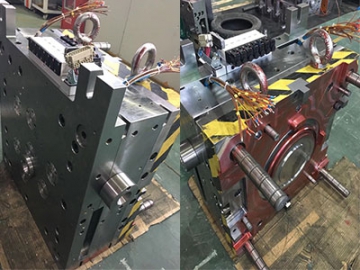

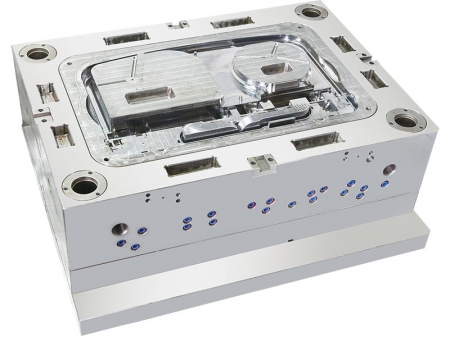

Structure:

Injection integrated oil-well pumps adopt a structure with a short pump barrel and long plunger. When the steam is injected, the lower pump barrel comes in contact with the pump, then the pump barrel coincides with the plunger slot and the steam enters into the heavy oil layer under the pump through the slot. Oil pumping is accomplished through the opening and closing of the inflow valve and flow valve.

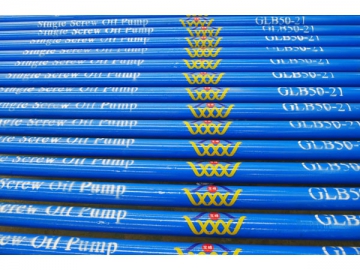

This whole set of progressive cavity pumps was delivered to Mongolia in July of 2016! For the moment, all of the heavy oil wells adopt whole sets of progressive cavity pumps to extract oil. The delivery head of our pump is 2000m, the displacement is 240m2 / d. It can lower power consumption by 60-75% compared to traditional pumps.

Technical Parameters:

| Nominal Diameter(mm) | Stroke Length (m) | THD Size | Max.OD(mm) | Clearance | |

| Tubing THD(in) | SR THD(in) | ||||

| φ38.1 | 1.8-6.0 | 2-7/8 TBG | 3/4 | Φ88.9 | II, III |

| Φ44.45 | Φ88.9 | II, III | |||

| Φ57.15 | 3-1/2 TBG | 3/4 or 7/8 | Φ108 | II, III | |

| Φ69.85 | Φ120 | II, III | |||