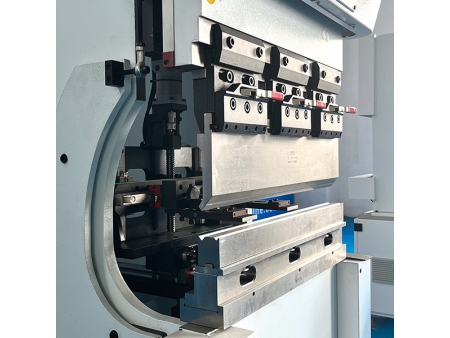

Electric Press Brake with Dual Cylinder

This press brake is equipped with a servo motor on both the left and right sides, applying force simultaneously for bending.The dual-cylinder design enhances stability and precision, making it ideal for medium to large-scale workpiece production, particularly in industries such as the automotive, shipbuilding, railway, and aerospace manufacturing sectors.The XSM series all-electric press brake operates without hydraulic oil, utilizing an electric cylinder drive, which eliminates hydraulic oil contamination and prevents temperature fluctuations from affecting machine precision.

The electric cylinder structure (Patent No. ZL202220140585.7) features a heavy-duty, high-precision ball screw, ensuring exceptional accuracy and long service life.During bending, the servo motor drives the electric cylinder, while minimal energy is consumed during rapid descent and return strokes, reducing energy consumption by over 50% compared to hydraulic press brakes.

- Material Carbon steel, alloy steel, aluminum alloy, copper alloy, high-speed steel, carbide alloy

- Length 10-2000mm

- Width 10-350mm

- Thickness 0.5-6mm

- Angle 0-180 degrees

- Accuracy 0.1-0.3mm

- Shapes V Shape, U Shape, Z Shape, L Shape

| Model | |||||

| Nominal Pressure (kN) | 120 | 180 | 300 | 400 | 500 |

| Workbench (mm) | 600 | 800 | 1250 | 1600 | 2000 |

| Column Spacing (mm) | 520 | 720 | 1160 | 1510 | 1900 |

| Throat Depth (mm) | 200 | 250 | 300 | 300 | 350 |

| Slide Stroke (mm) | 120 | 120 | 150 | 150 | 150 |

| Max. Opening Height (mm) | 450 | 420 | 450 | 470 | 480 |

| Backgauge Stroke (mm) | 200 | 350 | 500 | 500 | 500 |

| Max. Speed of Slider (mm/s) | 200 | 200 | 200 | 200 | 200 |

| Main Motor Power (kW) | 3*2 | 5.5*2 | 7*2 | 7.5*2 | 15*2 |

| Number of Axes | 4 (X, Y1, Y2, R) | 4 (X, Y1, Y2, R) | 4 (X, Y1, Y2, R) | 4 (X, Y1, Y2, R) | 4 (X, Y1, Y2, R) |

| Dimensions (L*W*H)(mm) | 1000*970*2100 | 1000*970*2100 | 1400*1200*2200 | 1750*1200*2200 | 2100*1200*2200 |

| Weight (kg) | 1250 | 1800 | 2350 | 3000 | 4200 |

-

The servo motor drives the electric cylinder during bending, consuming minimal power during rapid descent and return strokes. Compared to hydraulic press brakes, it reduces energy consumption by over 50%.

-

Operates without hydraulic oil, eliminating the risk of leaks and ensuring a clean and contamination-free workspace.

-

The combination of synchronous servo motors and ball screw transmission significantly enhances bending efficiency, providing faster and more precise operation.

-

The servo motor and high-precision ball screw ensure smooth and accurate vertical movement, maintaining long-term positioning precision even under continuous operation.